IRT-4N

Stainless Steel Pipe Size Run Tee – 1/4" FNPT x 1/4" MNPT x 1/4" FNPT

- Model: IRT-4N (1/4″ NPT pipe run tee, 316 stainless steel)

- Type: NPT Run Tee (female-male-female pipe tee)

- Material: 316 Stainless Steel (corrosion-resistant alloy)

- Connection Type: 1/4″ FNPT x 1/4″ MNPT x 1/4″ FNPT

- Pressure Rating: 7200 PSIG (Steel), 3600 PSIG (Brass)

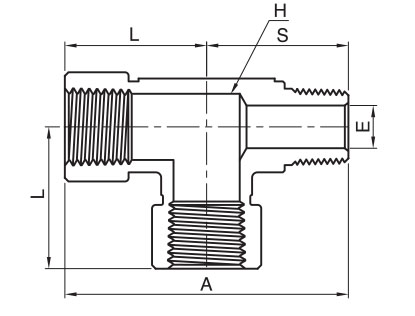

| Inch/Metric | Inch |

|---|---|

| Pressure Rating (Brass) | 248bar, 3600psig |

| Pressure [Max] | 496bar, 7200psig |

| Dimension A | 56.2mm |

|---|---|

| Dimension E | 7.1mm |

| Dimension H | 17.5mm |

| Dimension L | 29.0mm |

| Dimension S | 26.5mm |

Stainless Steel Pipe Size Run Tee – 1/4" FNPT x 1/4" MNPT x 1/4" FNPT (IRT-4N)

This 1/4″ NPT run tee is engineered for dependable service in pressurized gas and liquid systems where clean routing and long-term integrity are required. Combines strength and corrosion resistance with precise machining for consistent thread engagement. The female–male–female configuration provides flexibility in system design, allowing technicians to connect lines securely while maintaining a compact footprint.

Well-suited for pressure instrumentation, gas sampling assemblies, and hygienic fluid processing loops, this fitting helps engineers balance layout efficiency with reliable sealing. Its geometry supports directional routing in OEM skids, sampling panels, and industrial piping where connections must withstand continuous use. Because it integrates smoothly with compression fittings, manifolds, and other pipe-thread components, it adapts across both sanitary and industrial environments without compromising performance.

Engineered to hold up under vibration, temperature cycling, and pressure fluctuations, this component minimizes the risk of leaks in systems where uptime is critical. Whether used in clean-in-place (CIP) instrumentation, chemical transfer setups, or gas distribution networks, it provides durability and reliability for high-performance builds.

Key Benefits

Seal: NPT threads ensure reliable, leak-tight connections

Durability: Built for pressure cycling and corrosive environments

Flexibility: Compact tee layout for clean, directional routing

Compatibility: Connects with 1/4″ FNPT and MNPT sanitary components

Material: 316 stainless steel supports both sanitary and industrial builds

Typical Applications

- Hygienic fluid processing systems

- Clean gas or liquid sampling setups

- Valve manifolds and pressure instrumentation

- OEM skids and analytical panels

- Sanitary piping assemblies

Looking for a Swagelok® alternative? The IRT-4N delivers clean installation, system flexibility, and pressure-rated performance in demanding fluid control environments.

| Swagelok® | SS-4-ST |

|---|