Micron Inline Filter

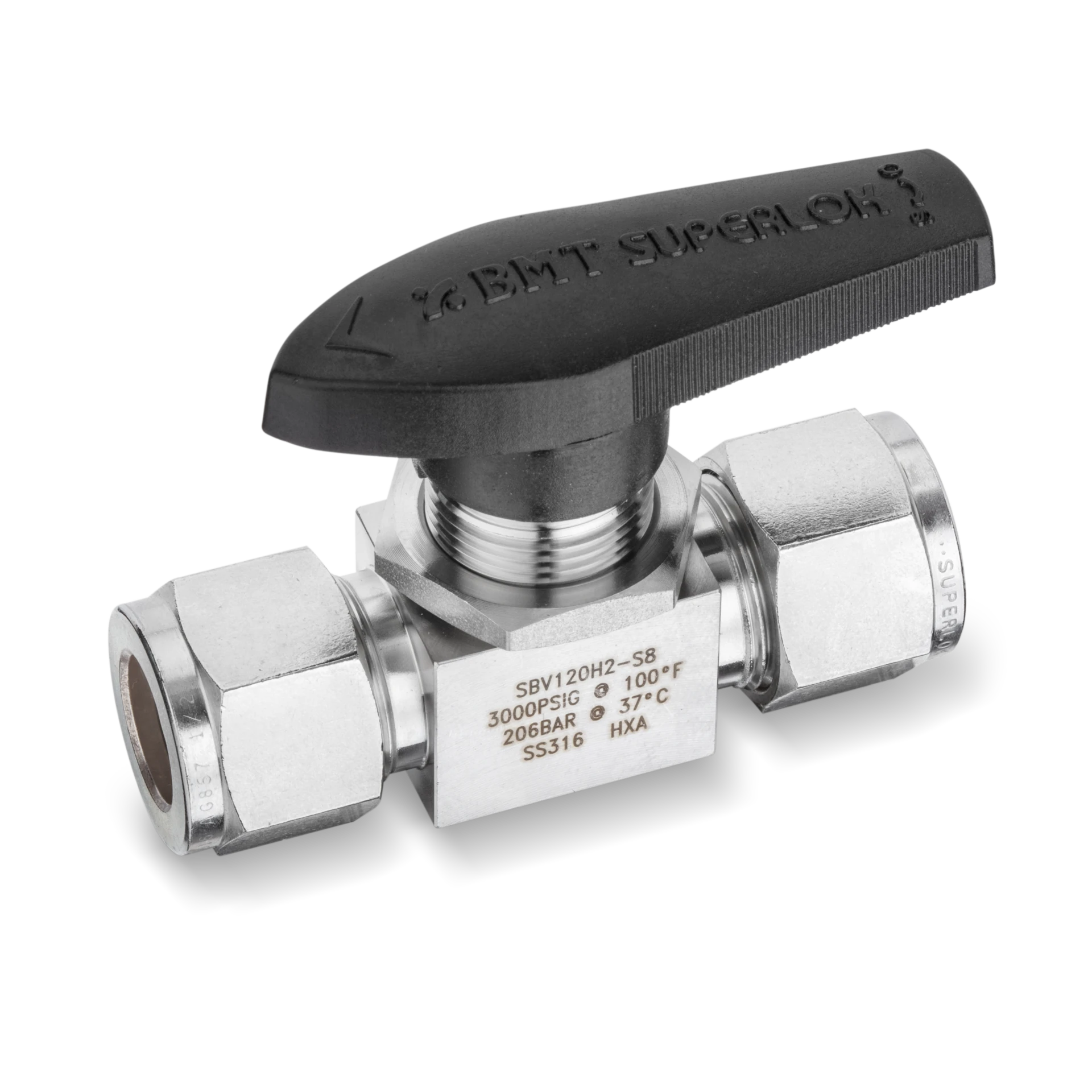

Micron Inline Filter by SuperlokUSA®

SuperlokUSA® micron inline filters are precision-engineered for high-efficiency contaminant removal in fluid and gas systems where cleanliness, pressure integrity, and system protection are critical. These filters are designed to intercept particulates and impurities before they compromise your equipment boosting reliability, extending component life, and reducing unplanned maintenance.

Constructed from 316 stainless steel and other corrosion-resistant alloys, Superlok micron inline filters stand up to harsh media, high-pressure differentials, and demanding operating environments. The result: long-lasting durability and consistent performance across industries that can’t afford failure like chemical processing, semiconductor manufacturing, pharmaceuticals, hygienic fluid processors, and gas distribution systems.

More Info

Types of Superlok Inline FIlter Valves

Swagelok® micron inline filters by Superlok

Swagelok® is known for high-performance filtration components but Superlok micron inline filters offer a trusted alternative with the same precision, reliability, and clean installation… without the markup or long lead times. Built to meet or exceed industry standards, Superlok filters deliver the quality you expect, plus better availability and value.

Each micron inline filter is manufactured from 316 stainless steel and designed for precise fluid control in sensitive or high-pressure applications. These micron inline filters feature leak-tight construction, high-flow capacity, and corrosion-resistant bodies that match or outperform equivalent Swagelok® models. And with compact inline designs, they install cleanly into both new builds and retrofit projects without compromise.

If you’re looking for a filtration solution that delivers top-tier performance, fast turnaround, and full pressure system reliability Superlok’s micron inline filters are the clear alternative.

Swagelok® Alternate Parts Near

All Superlok Micron Inline Filters are designed with the same dimensions and flow characteristics as Swagelok® and Parker® filters, allowing full cross-brand compatibility in fluid and gas systems. That means the same filtration performance, comparable form, fit, and function without the long lead times or markup. The internal components and end connections of Superlok filters are manufactured in accordance with ASME B31.3 for process piping and ASME B16.34 for pressure-containing parts. Thread tolerances are controlled per ASME B1.20.1, ensuring consistent sealing performance and leak-free integration every time.

To validate performance, Superlok’s inline filters undergo third-party testing for burst pressure, pressure drop, and particulate retention, and meet strict standards for use in sensitive and high-pressure filtration environments. For reference, we’ve attached the full SGS interchangeability & burst-test certification for your review.

Installation & Maintenance Best Practices

- Attach via male NPT finger-tight plus quarter-turn to 12 ft-lbs on 1/8-inch to 65 ft-lbs on 1/4-inch, gap-checking to validate seal without hose kinking in inline arrays.

- For high purity fluid processors, situate after pumps with bypass valves, fitting CIP ports for 260°F air blasts expelling residues under 0.05 micron absent core extraction.

- Fasten with beam clamps spaced 7 inches for expansion allowance, pursuing soap solution testing at 1.5 times MAWP over 8 minutes to rule out inline seepages.

- Overhaul yearly under HEPA for cartridge swap and housing swab with solvent-free wipes, trailed by agitation wash at 105°F and oxalic passivation to reinforce barriers to chloride corrosion in corrosion-resistant alloys.

- Reset indicators following 380°F runs, tabulating flow rates with rotameters for micron efficiency refinement.

- Archive cycle counts and turbidity logs, aligning with pipeline metrics for proactive element changes in batch runs.

- For volatile settings, embed flame-arrestor vents, ensuring retention surpasses 99.9% per NFPA 69 in vapor control lines.

These tactics amplify filter uptime to 35,000 hours, expediting rollouts in food processing and optics fabs. Tracked insights slash maintenance by 32%. Inline precision and cycling mandate secure purity universally with our micron inline filter.

Quality & Standards Compliance

- Cartridge seating follows ASME B16.5 flats of ±0.0007 inches, inspected via ring gauges and CMMs for delta-P steadiness within 4% aiding uniform inline scavenging.

- Core validation at 1.5 times RWP via MSS SP-51 uses argon for hold below 10^-6 scc/sec, looping 35,000 iterations to mirror extended runs without pleat collapse.

- Barrel straightness per ISO 1101 holds within 0.006 inches, CFD simulating 450 scfm for streamlined inline dynamics.

- Pairing with Donaldson®, Millipore®, and Cuno® validated by BSI blend assays, bearing 1,800 psig sans migration or blinding.

- Overpressure buffers hit 4 times RWP, etched in MTRs with phased array NDT for laminations under 0.0003 inches, per ASME Section XI.

- Argon affinity per ASTM G124 exposes no embrittlement at 2,500 psi, fatigue per ISO 1217 no loss after 1,200 hours.

- BSI independent probes feature retention scans and acoustic NDT for profile evenness below 0.001 inches, bestowing CoCs under ISO 9001:2015.

This blueprint forges filters for 16-year inline duty in headers and enclosures, topping criteria for debris defense in conduits. Provenance eases UL and SEMI inspections from feeds to drains. Fabrication finesse fuels peak filtration.

Frequently Asked Questions

What materials are Superlok micron inline filters constructed from?

What pressure ratings do these filters support?

Are Superlok filters compatible with other manufacturers' products?

How do I choose the right filter size?

What lead times apply to filter orders?

Can Superlok filters be used in high-purity applications?

How should unused ones be stored?

What torque specifications guide installation?

Do these filters accommodate cryogenic service?

Industry Leaders Using Superlok

Micron inline filters are widely used in industries that demand strict particulate control, long-term equipment protection, and consistent flow performance. These industries include oil and gas, chemical processing, pharmaceuticals, food and beverage, and semiconductor manufacturing.

Superlok’s Micron Inline Filters are engineered to meet the critical demands of these sectors, offering exceptional filtration performance, 316 stainless steel durability, and easy integration. Their corrosion-resistant design makes them ideal for aggressive media, while the precision-machined housings ensure leak-tight service even under high-pressure conditions.

These filters help extend system life, reduce maintenance frequency, and safeguard sensitive equipment. For hygienic fluid processors and industrial systems alike, Superlok delivers inline filtration that’s built to perform. Micron inline filters from Superlok provide the reliability and performance that today’s high-spec systems demand making them a preferred solution across critical applications worldwide.

Superlok Advantage

LARGEST INVENTORY OF MICRON INLINE FILTERS ALWAYS IN STOCK

SuperlokUSA maintains one of the most extensive inventories of micron inline filters in the country ready to ship directly from our U.S. warehouse to meet urgent timelines and reduce costly project delays. From standard high-flow filters to specialty configurations for sensitive fluid control, our deep inventory supports everything from fast-moving industrial builds to complex, multi-stage filtration systems. We stock filters in 316 stainless steel and other corrosion-resistant alloys, ensuring long-lasting durability in aggressive media environments. Paired with our consistent performance specs and third-party test data, Superlok inline filters are trusted by procurement teams, engineers, and system integrators who expect dependable performance and no last-minute surprises. This high availability, combined with Superlok’s quality and competitive pricing, makes us the preferred supplier for organizations seeking responsive, high-performance filtration alternatives to Swagelok® and other legacy brands.

FAST, RELIABLE DELIVERY ACROSS THE UNITED STATES

At SuperlokUSA, we understand that speed matters. That’s why we’ve built a nationwide logistics network to support same-day order processing and fast, traceable delivery on all micron inline filter orders no matter the scale. We partner with top-tier shipping providers and maintain special negotiated rates to ensure fast transit times and low freight costs even on bulk filter shipments or remote delivery locations. Whether you’re restocking for an MRO (Maintenance, Repair, and Operations) schedule or racing to meet a production deadline, Superlok makes sure your filters arrive when and where you need them. With rapid response, streamlined logistics, and premium-grade inline filters built to last, SuperlokUSA gives your team a real supply chain edge especially when timing and performance can’t be compromised.