Stainless Steel PIPE FITTINGS

Pipe Fittings by SuperlokUSA®

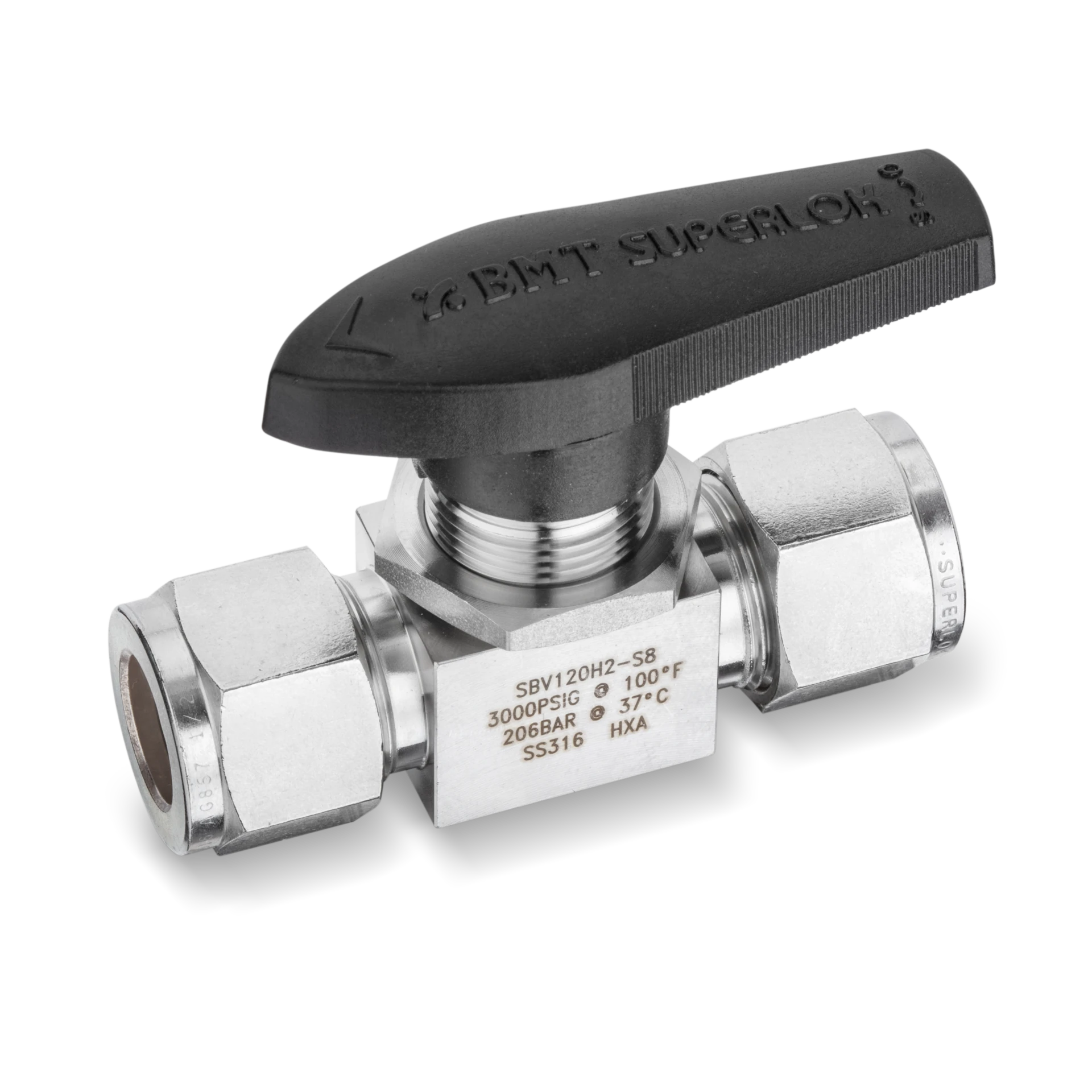

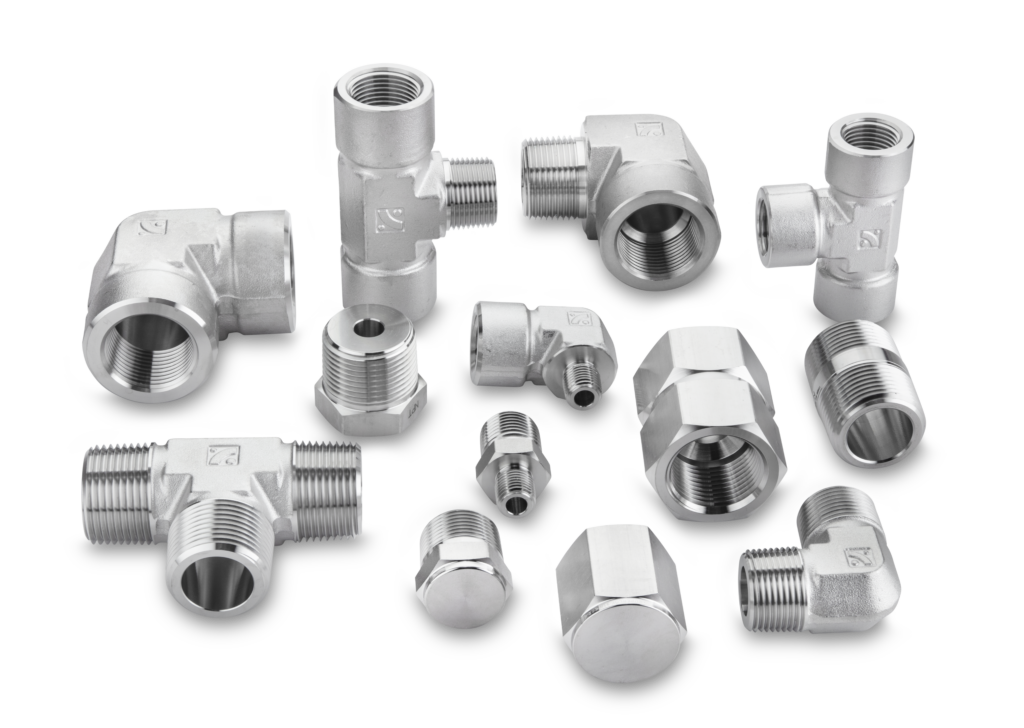

SuperlokUSA pipe fittings are engineered for durability, precision, and high-pressure performance in demanding fluid and gas pressure systems. Commonly used in oil and gas, chemical processing, food-grade manufacturing, and instrumentation, these fittings are designed to deliver long-term reliability and precise fluid control. With leak-tight connections and a robust construction, Superlok fittings help operators maintain system integrity under high stress and harsh environmental conditions.

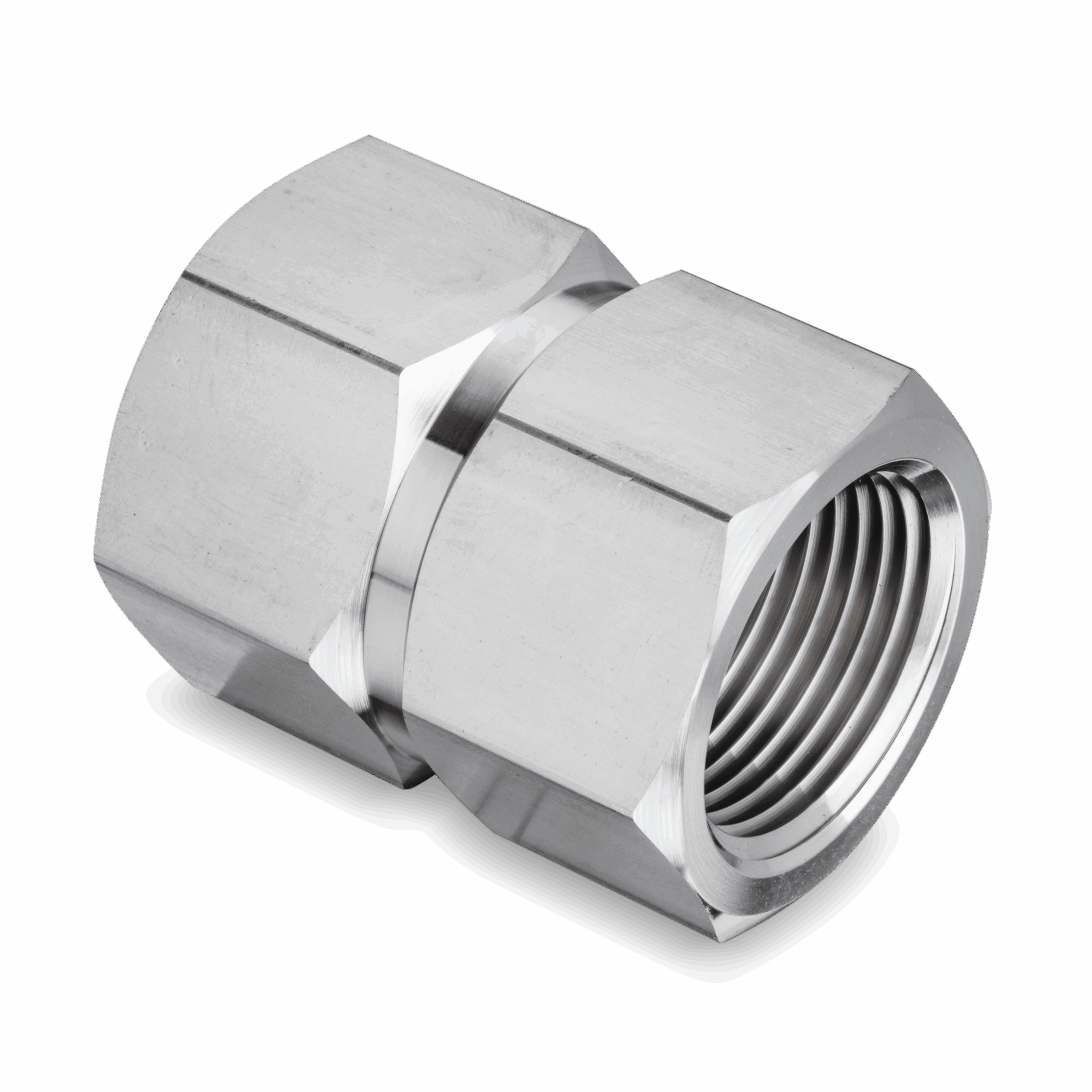

Offered in a wide variety of configurations including elbows, tees, couplings, and adapters SuperlokUSA pipe fittings are manufactured from corrosion-resistant alloys such as 316 stainless steel. Their tight tolerances, sanitary interior finish, and compatibility with clean-in-place systems make them a smart choice for sanitary stainless steel applications and hygienic fluid processors. Whether you’re designing a new pressure system or upgrading existing lines, these fittings provide seamless integration, reliable performance, and easier maintenance over time.

Request a quote today or call (805) 658-2043 to speak with a SuperlokUSA specialist. We’ll help you spec the right high-performance stainless steel pipe fittings for your application.

More Info

Each pipe fitting is engineered with a smooth internal bore to promote streamlined flow and reduce turbulence, which minimizes pressure loss and helps prevent contamination from particle buildup. This is especially critical in industries where cleanliness, purity, and uptime are top priorities. The result is a cleaner, more efficient system that requires less intervention and delivers consistent results while also contributing to lower operational costs and longer equipment life.

Stainless Steel Fractional Pipe Pressure Ratings

| Size Designator | NPT Size | 316 Stainless Steel | Brass | Carbon Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Male | Female | Male | Female | Male | Female | ||||||||

| psig | bar | psig | bar | psig | bar | psig | bar | psig | bar | psig | bar | ||

| 1 | 1/16 | 11000 | 757 | 6700 | 461 | 5500 | 378 | 3300 | 227 | 11000 | 757 | 6700 | 461 |

| 2 | 1/8 | 10000 | 689 | 6500 | 447 | 5000 | 344 | 3200 | 220 | 10000 | 689 | 6500 | 447 |

| 4 | 1/4 | 8000 | 551 | 6600 | 454 | 4000 | 27 | 3300 | 227 | 8000 | 551 | 6600 | 454 |

| 6 | 3/8 | 7800 | 537 | 5300 | 365 | 3900 | 268 | 2600 | 179 | 7800 | 537 | 5300 | 365 |

| 8 | 1/2 | 7700 | 530 | 4900 | 337 | 3800 | 261 | 2400 | 165 | 7700 | 530 | 4900 | 337 |

| 12 | 3/4 | 7300 | 502 | 4600 | 316 | 3600 | 248 | 2300 | 158 | 7300 | 502 | 4600 | 316 |

| 16 | 1 | 5300 | 365 | 4400 | 303 | 2600 | 179 | 2200 | 151 | 5300 | 365 | 4400 | 303 |

| 20 | 1 1/4 | 6000 | 413 | 5000 | 344 | 3000 | 206 | 2500 | 172 | 6000 | 413 | 5000 | 344 |

| 24 | 1 1/2 | 5000 | 344 | 4600 | 316 | 2500 | 172 | 2300 | 158 | 5000 | 344 | 4600 | 316 |

| 32 | 2 | 3900 | 268 | 3900 | 268 | 1900 | 130 | 1900 | 130 | 3900 | 268 | 3900 | 268 |

Swagelok® Alternative Pipe Fittings by Superlok

Swagelok® pipe fittings have long been the standard in high-pressure fluid and gas systems. But as costs rise and lead times stretch, Superlok offers a trusted alternative delivering comparable quality, leak-tight performance, and real-world affordability. In industries where system integrity and uptime are critical, Superlok pipe fittings help keep operations running without compromise.

Superlok’s pipe fittings are precision-machined from corrosion-resistant alloys and sanitary stainless steel, engineered for demanding environments like oil and gas, chemical processing, semiconductor fabrication, and pharmaceuticals. With consistent dimensions and reliable sealing, they offer a fully compatible alternative to Swagelok® backed by fast shipping and proven interchangeability.

For businesses that need performance without the premium, Superlok is the smarter choice. Their smooth interior finish promotes clean flow and reduces the risk of contamination, while their wide U.S. availability and easy installation make them ideal for both small-scale jobs and large system builds. Whether you’re replacing a single elbow or outfitting an entire line, Superlok pipe fittings are built to deliver.

Swagelok® Alternate Parts Near

Installation & Maintenance Best Practices

- Apply polytetrafluoroethylene (PTFE)-based thread sealant judiciously to male threads, torquing from 18 ft-lbs on 1/8-inch sizes to 120 ft-lbs on 1-1/2-inch diameters using a preset torque wrench calibrated to ±4% accuracy, preventing galling in corrosion-resistant alloys.

- For compression types, finger-tighten the nut before adding one-quarter turn with the mark-up tool, confirming ferrule bite depth of 0.010-0.015 inches to achieve metal-to-metal sealing without tube distortion.

- Position unions and elbows to minimize stress risers in pressure systems, supporting tubing with clamps spaced no more than 24 inches apart to counter vibration-induced fatigue.

- Conduct quarterly visual scans for thread erosion or crevice corrosion on 316 stainless steel, employing borescopes for internal checks and replacing if pitting depth surpasses 0.003 inches.

- Disassemble unions annually for debris removal via ultrasonic cleaning at 140°F with neutral pH solutions, followed by passivation in nitric acid baths to restore chromium oxide layers.

- Re-torque connections post-thermal cycling—up to 800°F in process lines—monitoring for leaks with electronic sniffers sensitive to 5x10^-7 scc/sec helium.

- Log torque sequences and test pressures in digital records, correlating with flow metrics to anticipate wear in precise fluid control applications.

Quality & Standards Compliance

Superlok components originate from 316 stainless steel forgings certified under ASTM A276/A479, exhibiting yield strengths over 30 ksi and impact toughness above 40 ft-lbs at -20°F, with sulfur content capped at 0.015% to mitigate stress corrosion cracking.

- Thread profiling adheres to ASME B1.20.1 tolerances of ±0.002 inches on pitch diameter, inspected via thread ring gauges and optical thread analyzers for crest root conformity.

- Material verification employs X-ray fluorescence positive material identification (PMI) on 100% of lots, cross-referenced against heat analysis certificates for molybdenum levels ensuring pitting resistance equivalent numbers (PREN) above 24.

- Hydrostatic burst testing to four times design pressure per ASME B31.3, with elongation measurements confirming ductility retention post-exposure.

- Sealing performance validates at 10^-6 standard cubic centimeters per second (scc/sec) via mass spectrometer leak detection, aligning with ISO 9001:2015 traceability mandates.

- Interchangeability confirms with Swagelok®, Parker®, and Hy-Lok® geometries through functional mockups, including pull tests exceeding 1,500 lbs on gripped ferrules.

- Finite element modeling simulates hoop stresses under 15,000 psi, optimizing wall thicknesses for finite life predictions over 10 million cycles in vibration spectra per ISO 6892.

Frequently Asked Questions

What materials are these constructed from?

Superlok pipe fittings feature 316 stainless steel construction for inherent corrosion resistance, meeting ASTM A403 specifications with controlled carbon levels under 0.03% to prevent sensitization in aggressive media. Brass variants suit low-pressure condensate lines, while Alloy 825 options tackle sour gas environments with enhanced molybdenum for pitting prevention.

What pressure ratings could these support?

Superlok socket weld fittings rate to 8,000 psig at ambient for 1/2-inch sizes, derating to 4,000 psig at 450°F per ASME B31.3 factors for sustained joint integrity. Threaded unions hold 5,500 psig cold non-shock, with elbows at 7,000 psig to accommodate dynamic loads in manifold assemblies.

Are Superlok pipe fittings compatible with other manufacturers' products?

Superlok fittings align dimensionally with Swagelok®, Parker®, and Hy-Lok® standards, including NPT per ASME B1.20.1 and socket depths with matching tolerances for seamless swaps. This enables drop-in integration in existing pipe runs without velocity changes or adapter needs in hybrid systems.

How do I choose the right size?

Measure nominal pipe size (NPS) by outer diameter and schedule thickness, then consult Superlok catalogs for corresponding socket or thread profiles to ensure full engagement. For high purity fluid processors, opt for schedule 40 designs to limit pressure drops below 1 psi per 100 feet in laminar gas flows.

What lead times apply to these orders?

In-stock configurations ship same-day from domestic hubs, facilitating quick turnaround for standard NPT and socket weld types. Custom radii or exotic alloys require 3-5 weeks fabrication, expedited to 6-9 days via priority milling for urgent pipeline repairs.

Can these be used in high-purity applications?

Yes, electropolished variants achieve Ra 8 micro-inch bores, certified ultra-low particle per ISO 14644 Class 4 for pharma water systems and etchants. They withstand 180+ CIP cycles without extractables above 20 ppb, supporting seamless integration in clean manifolds.

How should unused ones be stored?

Store in controlled zones at 45-75°F with humidity under 45%, separated from contaminants to preserve thread and socket integrity. Use sealed pouches with desiccants for up to 4-year holds, inspecting for oxidation via borescope before jointing in process lines.

What torque specifications guide installation?

For 1/4-inch NPT, apply 25 ft-lbs initial then verify snug after proofing to prevent leaks at operating pressure. Larger 1-inch sizes cap at 90 ft-lbs with calibrated tools, reducing 15% for soft-seated variants to avoid distortion in sanitary setups.

Do these accommodate cryogenic service?

Superlok fittings operate to -300°F with impact toughness exceeding 45 ft-lbs, ideal for helium transfer lines per ASTM E23 testing. Derates below -150°F ensure no brittle failure, with expanded sockets compensating for contraction in cryo pumps.

Industry Leaders Using Superlok

Superlok pipe fittings are trusted across industries where precise fluid control, system cleanliness, and reliable sealing are essential. From oil and gas to chemical processing, pharmaceuticals, food and beverage, and semiconductor manufacturing these fittings support demanding pressure systems that require frequent assembly, disassembly, and maintenance.

Manufactured from corrosion-resistant alloys and sanitary stainless steel fittings, Superlok pipe fittings offer leak-tight performance in high-pressure environments and hygienic fluid processors alike. Their precision-machined design supports clean-in-place instrumentation and reduces contamination risk, making them an ideal fit for hygienic valves, sterile production areas, and systems requiring uncompromised fluid integrity.

Whether maintaining ultra-clean fluid paths in food-grade applications or managing high-pressure gas lines in a refinery, Superlok pipe fittings are engineered for lasting performance. Their smooth interior finish reduces turbulence and improves system efficiency, while the durable construction supports long service life in both sanitary and industrial systems. For operations that demand safety, speed, and reliability Superlok delivers across the board.

Superlok Advantage

MASSIVE INVENTORY OF PIPE FITTINGS READY TO SHIP

SuperlokUSA stocks one of the largest inventories of pipe fittings in the United States ready to ship fast, coast to coast. Whether you're replacing a single elbow or sourcing bulk for high-pressure fluid systems, our deep stock ensures you get what you need without costly delays. All fittings are manufactured from corrosion-resistant alloys and sanitary stainless steel, supporting critical pressure systems where reliability matters. With minimal lead times and full system compatibility, Superlok gives you the flexibility to move fast no backorders, no excuses, and no waiting on Swagelok®.

FAST, RELIABLE DELIVERY ACROSS THE USA

SuperlokUSA offers industry-leading delivery speeds for pipe fittings across the U.S., helping teams avoid project delays and unplanned downtime. Thanks to our nationwide distribution network and low negotiated shipping rates, your order arrives quickly without premium freight charges. Every pipe fitting is precision-machined, pressure-ready, and backed by reliable service. Compared to Swagelok®, where lead times and shipping costs are often unpredictable, SuperlokUSA delivers consistent value. From routine maintenance to emergency replacements, our speed and scale make SuperlokUSA a trusted source for fluid and gas control systems nationwide.