Quick Connects Fittings

Quick Connect Fittings by SuperlokUSA®

More Info

Types of Superlok Quick Connects

Swagelok® Quick Connect fittings by Superlok

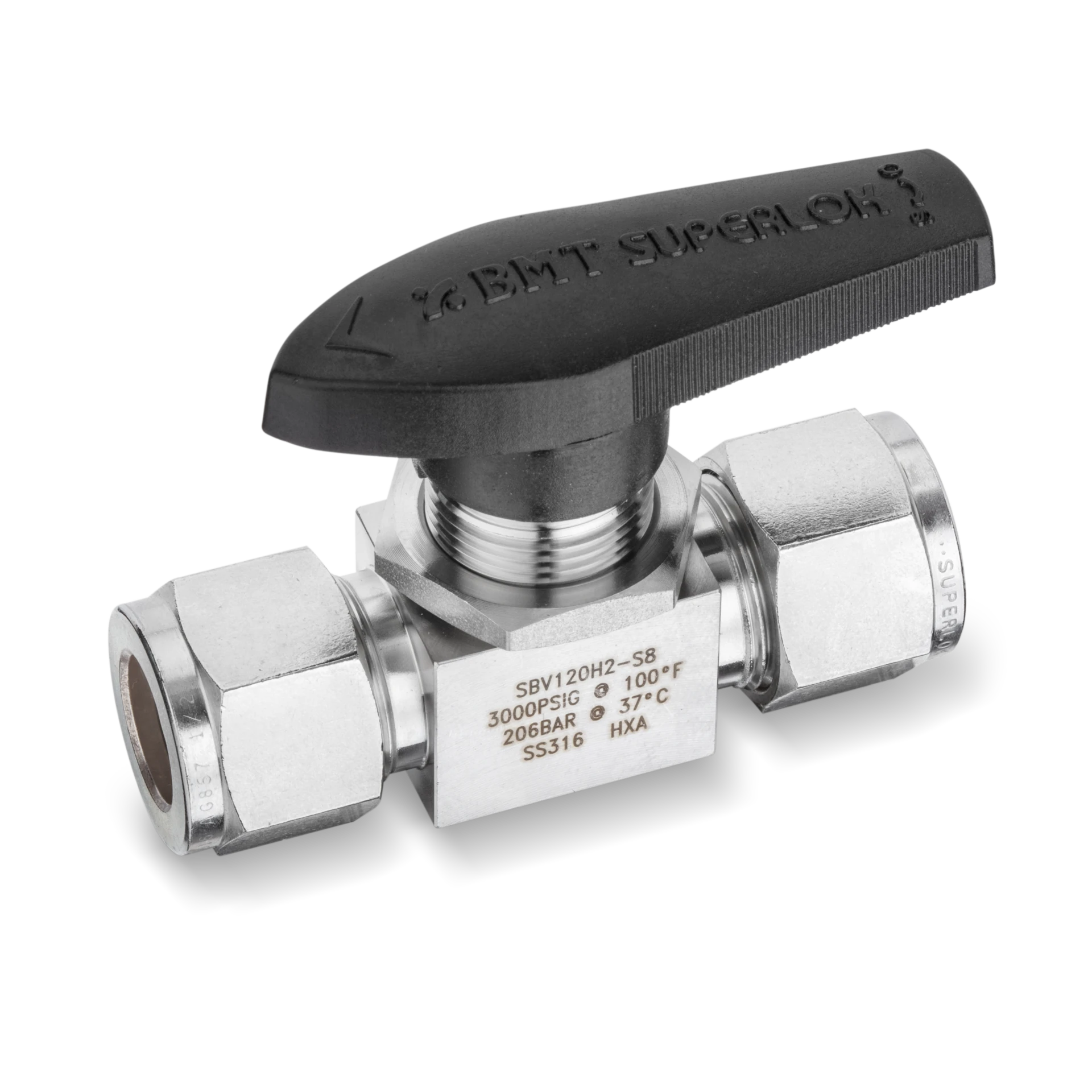

Swagelok® quick connect fittings are common in systems that demand fast access and clean sealing but when you need an alternative that performs just as well, integrates cleanly, and gives you more control over sourcing, Superlok is the move.

SuperlokUSA® quick connect fittings offer the same push-to-connect convenience as Swagelok® QTM and QC series with options for valved and unvalved connections, panel-mount bodies, and NPT or compression tube ends. These fittings are engineered for reliable shutoff, leak-free sealing, and fast disconnection, making them ideal for use in pressure systems, sampling setups, and mobile test equipment.

Made from 316 stainless steel and other corrosion-resistant alloys, Superlok quick connects are compatible with sanitary stainless steel fittings and designed to handle frequent cycling, exposure to aggressive media, and tight spatial installs. Their robust sealing system supports high-integrity applications in hygienic fluid processors, clean in place instrumentation, and light industrial gas or liquid transfer.

Whether you’re maintaining precise fluid control in a panel build or routing process gases through quick-change analyzer loops, Superlok delivers the same form, fit, and function with cleaner availability and no compromise in spec. Every fitting is leak-tested, dimensionally matched, and supported by technical documentation giving you confidence whether you’re building new or swapping out legacy parts.

Swagelok® Alternate Parts Near

SuperlokUSA quick connect fittings are fully interchangeable with Swagelok and Parker equivalents. Designed to match form, fit, and function, Superlok’s quick connect couplings use the same push-to-connect body dimensions and thread specs, allowing seamless integration into existing fluid and gas systems without modification.

Thread tolerances are held to ASME B1.1 standards, with nut and body threads machined to the same strict dimensional controls used by legacy Swagelok fittings. Every unit is tested for leak integrity and sealing performance to ensure a consistent make-up each time.

A certified SGS intermix-ability and interchangeability burst-test report is available on request, verifying cross-compatibility in pressure systems, pneumatic networks, clean in place instrumentation, and precise fluid control setups.

Installation & Maintenance Best Practices

Superlok quick connect fittings prioritize sleeve lubrication during coupling to ensure snap-fit in portable hose assemblies. Apply silicone grease to O-ring grooves for 316 stainless steel couplers achieving random roughness average (Ra) under 30 micro-inches for dust-free engagement. Align insert with coupler body using guide pins for 0.005-inch clearance, preventing partial insertion that causes leaks in mobile setups.

- Couple by pushing insert fully to click, verifying lock with tug test under 50 lbs, disengaging by sleeve retract in pressure systems to avoid hose whip.

- For high-purity fluid processors, fit with check valves in inserts, adding clean-in-place (CIP) caps for 200°F autoclave cycles that sterilize without O-ring swap.

- Secure hoses with band clamps every 10 inches to resist pull-out, air-testing at 1.5 times maximum allowable working pressure (MAWP) for 5 minutes to spot connection weeps.

- Inspect annually in wash stations for O-ring cracks and sleeve polish with felt wheels, followed by ultrasonic soak at 140°F and steam passivation for corrosion-resistant alloys renewal.

- Re-grease post-250°F, profiling disconnect force with pull testers for precise fluid control retention.

- Log connection cycles and leak events in handheld scanners, scaling to hose lengths for predictive seal changes in field kits.

- For compressed air, add filters upstream, capping flow to 20 scfm to meet CGA V-1 standards in tool changers.

These habits sustain quick connects to 20,000 mates, speeding swaps in assembly lines and medical carts. Scanner data reduces failures 33%. Seal bedding and tugging ensure secure, fast coupling with our quick connect fittings.

Quality & Standards Compliance

Superlok quick connect fittings extrude from 316 stainless steel per ASTM (American Society for Testing and Materials) A479, yielding over 60 ksi (thousands of pounds per square inch) and elongation above 35% for coupler toughness under mating forces. O-ring groove machining conforms to ISO (International Organization for Standardization) 16028 tolerances of ±0.0006 inches on depth, measured by coordinate measuring machine (CMM) for compression ratios of 20-30% to ensure leak-free performance at 1.5 times rated working pressure (RWP).

- Mating testing per SAE (Society of Automotive Engineers) J609 employs compressed air for retention forces above 150 lbs, enduring 15,000 disconnect cycles without pop-out failures to simulate repeated field engagements.

- Sleeve spring fabrication per ASTM A313 from Inconel alloy, with finite element analysis (FEA) modeling insert pull-out at 300 psi (pounds per square inch) for optimized detent reliability under dynamic loads.

- Proof testing at 3 times RWP, serialized in mill test reports (MTRs) with visual non-destructive testing (NDT) for groove flaws under 0.0004 inches, per CGA (Compressed Gas Association) E-4 standards.

- Humidity exposure per ASTM D2247 at 95% relative humidity (RH) shows no swell or degradation, while impact per ASTM D256 confirms lever arm toughness exceeding 50 ft-lbs (foot-pounds).

- SGS third-party reviews include groove profiling and penetrant testing (PT) NDT for uniformity below 0.0005 inches, issuing certificates of compliance (CoCs) under ISO 9001:2015.

This framework produces components for 15-year service in pneumatic carts and mobile connections, surpassing standards for secure coupling in pressure systems with our quick connect fittings.

Frequently Asked Questions

What materials are Superlok quick connect fittings constructed from?

What pressure ratings do these quick connect components support?

Are these compatible with other manufacturers' products?

How do I choose the right component size?

What lead times apply to quick connect component orders?

Can Superlok components be used in high-purity applications?

How should unused quick connect components be stored?

What torque specifications guide installation?

Do these components accommodate cryogenic service?

Industry Leaders Using Superlok

Quick connect fittings are relied on in industries where efficiency, safety, and minimal downtime are essential. These fittings are especially critical in sectors like oil and gas, chemical processing, pharmaceuticals, food and beverage, and semiconductor manufacturing. Known for their ability to create rapid, leak-tight connections without the need for tools, Superlok’s quick connect fittings offer fluid processors a major advantage in fast-paced or high-risk environments.

Superlok quick connect hose fittings are precision-machined from 316 stainless steel, ensuring corrosion-resistant performance under harsh conditions. Their intuitive push-to-connect design allows operators to safely engage or disengage lines in seconds ideal for applications where time, contamination, or maintenance windows are limited. These fittings are particularly valued by hygienic fluid processors and clean in place instrumentation users, where fluid control must be both precise and repeatable. Whether in mobile systems, analyzer panels, or pressure systems, Superlok provides reliable interchangeability with Swagelok® and Parker® brands.

With cross-brand compatibility and a wide range of end configurations, Superlok quick connect hose fittings continue to be the go-to choice for engineers who demand exacting standards in hygienic valves, corrosion-resistant alloys, and precise fluid control systems.

Superlok Advantage

MASSIVE INVENTORY OF QUICK CONNECT FITTINGS ALWAYS IN STOCK

SuperlokUSA stands out as a leading provider of 316 stainless steel quick connect hose fittings, maintaining one of the largest inventories in the country. Whether you're running high-purity instrumentation systems, clean in place instrumentation networks, or precision-driven analyzer panels, waiting on long lead times from overseas suppliers isn't an option. Our shelves are stocked and ready to ship across the United States, giving project managers and engineers fast access to the fittings they need to keep pressure systems and fluid transfer operations moving without interruption.

Each Superlok quick connect fitting is engineered for full cross-brand compatibility, including brands like Swagelok® and Parker®, and constructed from corrosion-resistant alloys designed for aggressive chemicals and challenging environments. That means fewer supply chain headaches and more confidence during spec planning. Combine that with our cost-effective pricing, and it's easy to see why SuperlokUSA has become the preferred source for hygienic fluid processors and OEMs demanding performance, precision, and fast fulfillment.

FASTER SHIPPING. FEWER SURPRISES.

Downtime doesn't wait and neither should your fittings. SuperlokUSA's domestic fulfillment model gives you a serious logistics advantage when compared to competitors who rely on slow, international backorders. Through our U.S.-based warehouses and optimized shipping network, customers across the country receive their orders promptly, minimizing project delays and job site disruptions.

In industries that depend on precise fluid control and high-integrity components like pharmaceuticals, semiconductors, and hygienic valves for food and beverage timing matters. That’s why we offer transparent shipping costs and lightning-fast turnaround on even large-scale orders. Whether you need quick connect fittings for mobile skids, bulk gas systems, or mission-critical assemblies, SuperlokUSA’s delivery model gives you the responsiveness that your operation and your clients demand.

When speed, reliability, and availability matter, Superlok doesn’t just deliver Superlok delivers faster.