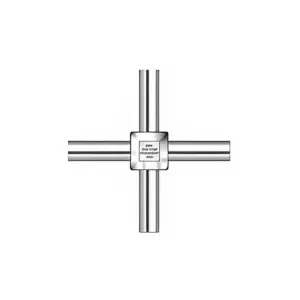

Every part comes out of a controlled production space. Air filtered. Handling’s limited. Nothing enters the process that doesn’t belong there. The goal is to keep surfaces clean and consistent, not just at the start but years down the line. Internal passages are straight and open, so flow stays smooth and pressure readings don’t drift. The 316 stainless steel stands up to chemical washes, steam, and temperature swings without wearing down or losing its shape. That corrosion-resistant build is what keeps the system honest.

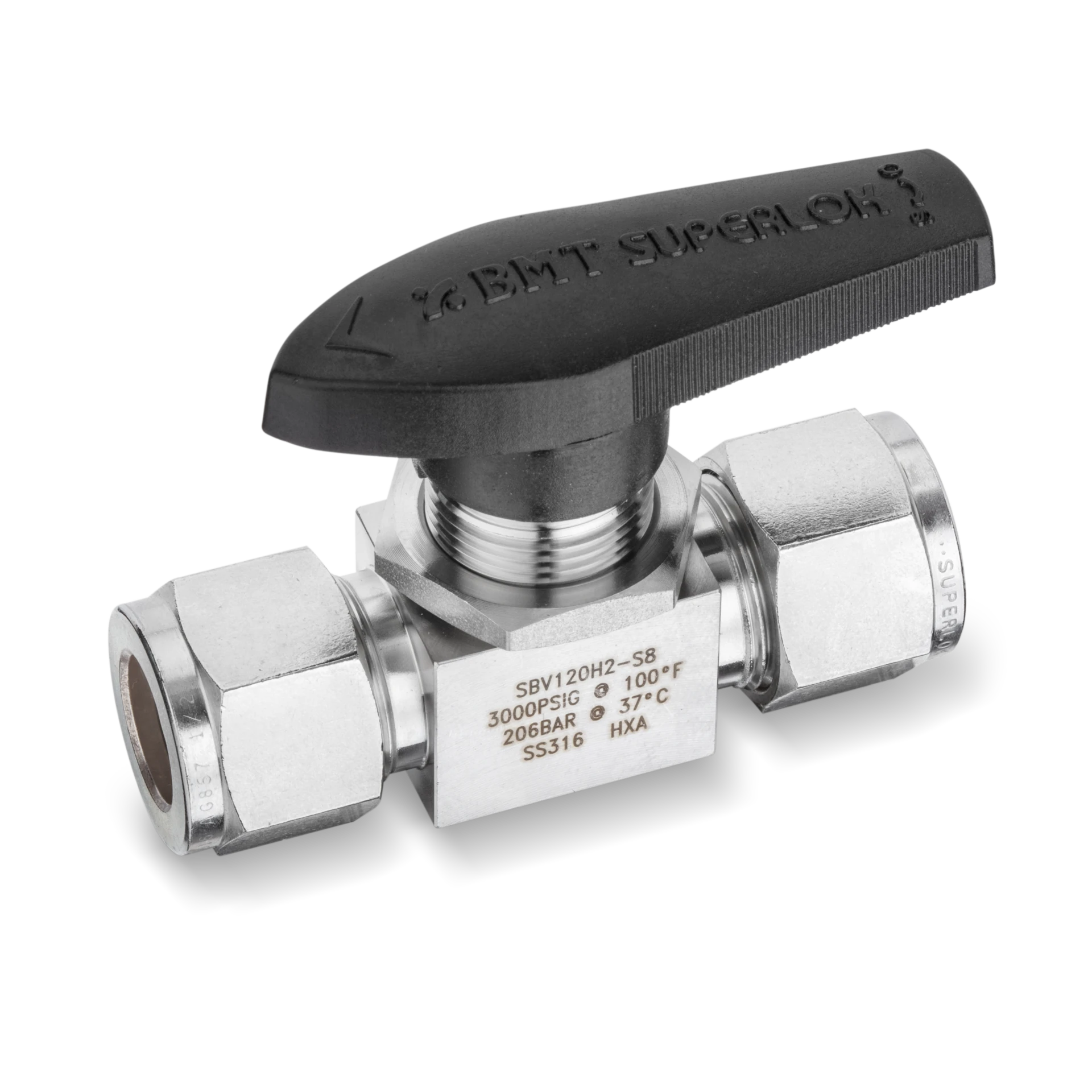

These components live in Clean-in-Place (CIP) and Sanitary-in-Place (SIP) setups, fluid systems, and clean-room instrumentation where cleanliness isn’t a nice-to-have – it’s the rule. Each one goes through surface checks and seal tests to confirm purity and strength before it ever leaves the bench. Smooth flow, no turbulence, no buildup. That’s the standard. And when it’s used in pressure systems or chemical lines that run nonstop, that polish, that consistency, is what keeps everything steady.

Designed for Precision and Performance

Each connection holds tight, seals clean, and doesn’t quit when it’s heat-cycled, sterilized, or broken down for maintenance and rebuilt again. Every part is built to survive repetition, the daily wear, the temperature swings, the constant pressure changes, and still seal like it’s brand new.

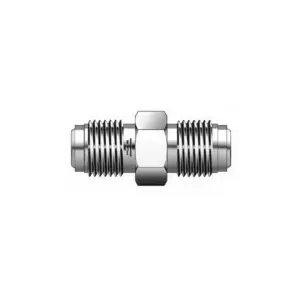

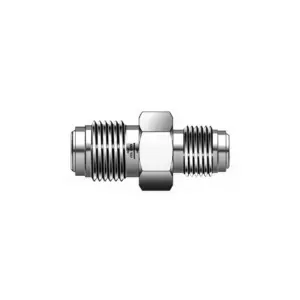

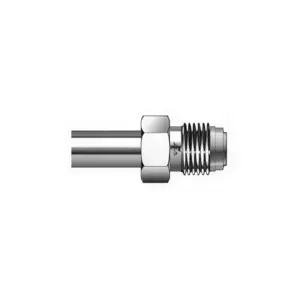

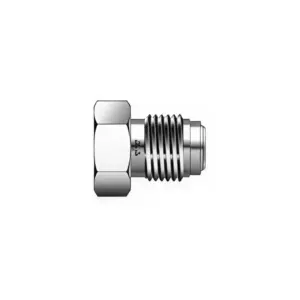

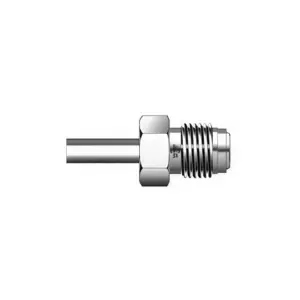

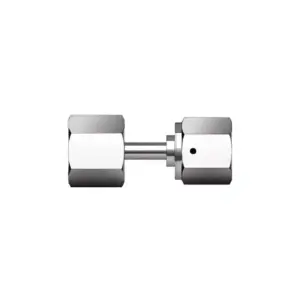

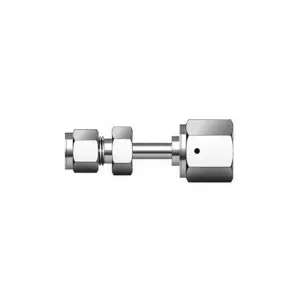

- Ultra High Purity Weld Connections: Used for clean, permanent joints where the line needs to stay fixed and contamination-free. The weld zones are smooth, easy to sanitize, and maintain full structural integrity under pressure and thermal stress.

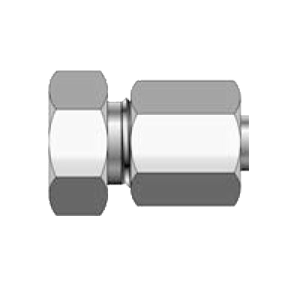

- Ultra High Purity Face Seal Connections: Built for repeatable, tight sealing where assemblies are frequently opened or adjusted. The face-to-face metal contact and surface polish eliminate dead space, keeping every reconnect just as clean as the first install.

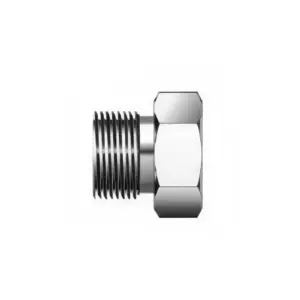

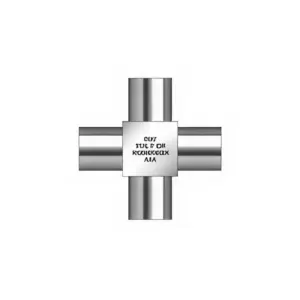

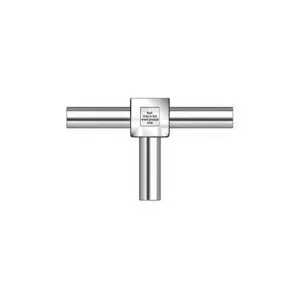

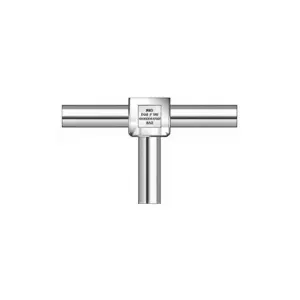

- Ultra High Purity Elbows and Reducers: Made for stable directional changes and size transitions without turbulence or flow disruption. The geometry keeps velocity consistent, reduces drag, and prevents particle buildup in corners, ensuring purity stays intact through every bend in the system.

Why SuperlokUSA®

Leak-Tight Reliability: Every seal is tested under sustained pressure to ensure it holds clean, steady, and repeatable performance, no leaks, no rework, no downtime, even under the toughest operating conditions or extended thermal cycles common in industrial service.

Corrosion-Resistant Construction: Built from 316 stainless steel, each component stands up to harsh cleaning agents, high heat, chemical exposure, and long-term use without degradation, pitting, or surface discoloration, maintaining strength and appearance through years of demanding system operation.

Dimensional Consistency: Every thread, seat, and bore is matched, measured, and checked to maintain perfect fit and alignment, ensuring compatibility and repeatable precision across multiple production runs for dependable performance in every high-pressure or high-purity setup.

Cleanroom Handling: Produced, inspected, and packaged in controlled environments suitable for clean-room instrumentation, pharmaceutical applications, and other high-purity processes where contamination cannot be tolerated, ensuring each component arrives clean, sealed, and ready for immediate system integration.

System Compatibility: Works seamlessly with Clean-in-Place (CIP) and Sanitary-in-Place (SIP) configurations, integrating cleanly into complex pressure systems and fluid systems without disrupting flow, balance, or mechanical integrity, maintaining stable performance under varied load and temperature conditions.

Swagelok® Alternative: Fully compatible with Swagelok® components, offering the same precision, long-term reliability, and clean installation fit, all at a more practical cost for large-scale or repeat system builds without compromising material quality or pressure capability.

All SuperlokUSA®’s parts are built to last, clean, corrosion-resistant, and ready for the systems that demand the best. Each piece is precision-machined, inspected, and finished to meet the same high standards across every batch. They don’t just perform when new; they keep performing after years of pressure, cleaning, and continuous use.

Need reliable 316 stainless steel components for high-purity and pressure systems? Add them to your cart below to request a quote.