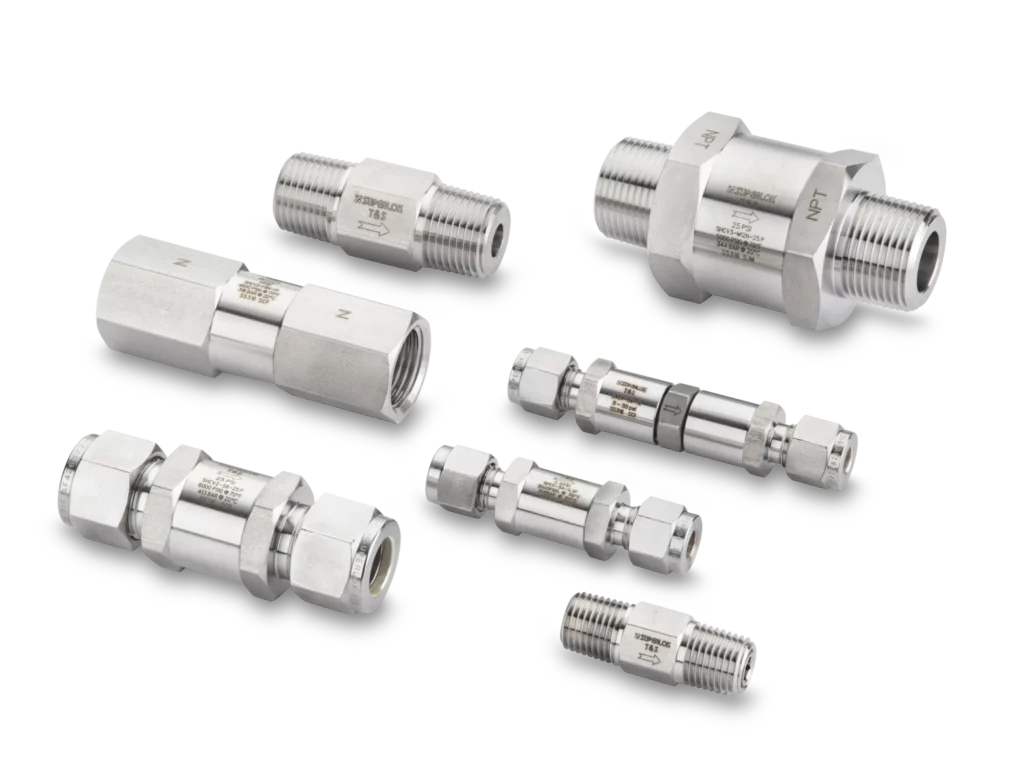

Our check valves include adjustable cracking pressure options, allowing users to customize opening pressures based on system requirements. Whether for industrial processing, gas distribution, or critical instrumentation, SuperlokUSA® check valves provide unmatched reliability in high-pressure environments.

Superior Flow Control and Sealing Performance

SuperlokUSA® check valves are built to ASME, API, and ISO industry standards, ensuring compliance with global safety and performance regulations. Manufactured from 316 stainless steel, these valves provide exceptional corrosion resistance and long-term durability, making them ideal for harsh operating conditions.

Our selection includes:

- SACV Adjustable Check Valves – Featuring customizable cracking pressure settings, allowing for precise flow control in demanding applications.

- SHCV Check Valves – Designed for high-flow efficiency, ensuring leak-proof backflow prevention in hydraulic and gas systems.

- SOACV Adjustable Check Valves – Ideal for chemical and instrumentation systems, offering controlled pressure release with a compact design.

- SOCV One-Piece Check Valves – Built for minimal maintenance and robust operation, ensuring consistent, secure fluid flow.

- SPCV Check Valves – Optimized for high-pressure applications, maintaining leak-free sealing even in extreme conditions.

Why Choose SuperlokUSA® Check Valves?

Reliable Backflow Prevention: Designed to maintain unidirectional flow, eliminating risks of reverse flow contamination.

Leak-Proof Sealing: Precision spring-loaded mechanisms ensure tight sealing under high-pressure conditions.

High-Quality Materials: Made from 316 stainless steel, delivering maximum corrosion resistance and durability.

Versatile Applications: Ideal for petrochemical, instrumentation, hydraulic, and compressed gas systems.

Certified Performance: Compliant with ASME, ISO, API, and ANSI standards, ensuring safe and efficient operation in industrial environments.

Swagelok® Alternative: Fully compatible with Swagelok® check valves, providing a cost-effective and high-performance solution.

Each SuperlokUSA® check valve delivers unparalleled safety, performance, and reliability for critical fluid control applications.

Browse our products today to find the perfect check valve for your system!