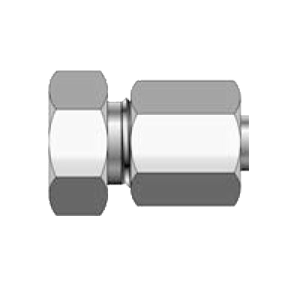

SRUT-6S-6S-4S - Stainless Steel Reducing Union Tee 3/8" O.D. x 3/8" O.D. x 1/4" O.D. (Single Ferrule)

- Model: SRUT 6S-6S-4S (3/8″ outer diameter (O.D.) x 3/8″ O.D. x 1/4″ O.D. reducing union tee (single ferrule))

- Type: Reducing Union Tee (Single Ferrule)

- Material: 316 Stainless Steel (corrosion-resistant alloy)

- Pressure Rating: Designed for pressure systems

- Size: 3/8″ O.D. x 3/8″ O.D. x 1/4″ O.D.

- Finish: Polished for secure connection

(SRUT-6S-6S-4S - Stainless Steel Reducing Union Tee 3/8" O.D. x 3/8" O.D. x 1/4" O.D. (Single Ferrule))

The Superlok SRUT 6S-6S-4S is a cutting-edge reducing union tee, forged from 316 Stainless Steel, a corrosion-resistant alloy, to connect tubes with outer diameters of 3/8″ and 1/4″ in a T-shaped single-ferrule design. Built for pressure systems, it ensures precise fluid control, making it a prime choice for high purity fluid processors. The polished finish enhances clean in place instrumentation, delivering superior performance in compact, high-purity setups. With sanitary stainless steel fittings, its robust construction conquers the harshest conditions.

Tailored for pulp processing and oil and gas transport, this tee blends durability with exceptional strength. Resists corrosive gases, temperature shifts, and rigorous cleanings, guaranteeing long-term reliability in high purity environments. It pairs flawlessly with standard fittings, reducing contamination risks in gas networks.

Installation is seamless, with a finish that minimizes fouling and simplifies maintenance. The SRUT 6S-6S-4S ensures a secure, leak-free connection under pressure, accelerating assembly in OEM fluid systems. Its innovative design supports modular process lines, boosting efficiency with consistent adaptability. This component helps operators avoid costly halts, maintaining efficiency across the system.

Key Benefits

- Seal Reliability: Leak-free performance during continuous duty cycles

- Oxidation Resistance: Surfaces withstand chemical and environmental attack

- High-Purity Design: Smooth flow paths support sterile processes

- Service Simplicity: Straightforward assembly reduces downtime

- Flow Consistency: Precision machining ensures predictable delivery

Typical Applications

- Pulp processing units

- Oil and gas transport

- Chemical processing plants

- Paper production lines

- OEM fluid assemblies

Choose the SRUT 6S-6S-4S for reliable, high-performance engineering in your critical systems.