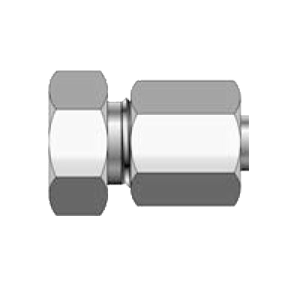

SHCV2-S-6-1P

Stainless Steel 3/8" Check Valve – 6000 psi, Male NPT

- Model: shcv2-s-6-1p (3/8 in. check valve, stainless steel, NPT male ends)

- Type: In-line Check Valve (one-way flow control with spring-loaded poppet)

- Material: 316 Stainless Steel (corrosion-resistant alloy)

- Pressure Rating: 6000 psi working pressure

- Cracking Pressure: 1 psi nominal (#1 spring)

- Connections: 3/8 in. Male NPT (National Pipe Tapered)

- Finish: Machined and polished for hygienic and sanitary-grade systems

| Back Pressure at 70 (20 ?C) Temperature | 413bar, 6000psig |

|---|---|

| Cv Coefficient | 1.8 |

| End Size | 44263mm |

| Inch/Metric | Inch |

| Nominal Cracking Pressure | 0.068bar, 1psig |

| Operating Pressure [Min] | 413bar, 6000psig |

| Orifice | 7.8mm |

| Reseal Pressure [Min] | 0.34bar, 5psig |

| Temperature Rating for Ethylene Propylene | -45 to 148?C, -50 to 300?F |

| Temperature Rating for Fluorocarbon (FKM) | -23 to 190?C, -10 to 375?F |

| Temperature Rating for Nitrile Butadiene Rubber | -23 to 121?C, -10 to 250?F |

| Dimension A | 69.9mm |

|---|---|

| Dimension B | 31.2mm |

| Dimension h | 1in, 25.4mm |

Stainless Steel 3/8" Check Valve – 6000 psi, Male NPT (SHCV2-S-6-1P)

The shcv2-s-6-1p is a compact in-line stainless steel check valve designed to deliver dependable one-way flow control in high-pressure and sanitary fluid systems. Its 316 stainless steel construction provides long-term durability, excellent chemical resistance, and suitability for both industrial and hygienic environments.

With a 1 psi cracking pressure and 6000 psi working capacity, this check valve supports the performance needs of hygienic fluid processors and pressure systems requiring fast response and tight shutoff. It integrates seamlessly into systems using sanitary stainless steel fittings, making it ideal for pharmaceutical, food-grade, and biotech installations.

This component is especially compatible with clean in place (CIP) instrumentation, supporting precise fluid control in Original Equipment Manufacturer (OEM) skids, process panels, and tubing assemblies. It also complements hygienic valves used across CIP (Clean-in-Place) loops and critical backflow prevention points.

Key Benefits

- Pressure-rated for up to 6000 psi in demanding pressure systems

- Low 1 psi cracking pressure allows sensitive and responsive flow initiation

- Machined from 316 stainless steel and other corrosion-resistant alloys

- Threads directly into 3/8" NPT (National Pipe Tapered) connections

- Supports clean in place (CIP) instrumentation and high-purity process loops

Typical Applications

- OEM (Original Equipment Manufacturer) and sanitary skids

- Hygienic valves and CIP (Clean-in-Place) return lines

- Hygienic fluid processors

- Biotech gas and liquid networks

- Backflow prevention in high-purity pressure systems

| Swagelok® | SS-CHS6-1 |

|---|