SINV3-S-8-RS

Stainless Steel Needle Valve – 1/2" FNPT x FNPT, 5000 psi, Hygienic Regulating Stem

- Model: SINV3-S-8-RS (1/2" Female National Pipe Taper (FNPT) inlet and outlet)

- Type: Inline Hygienic Needle Valve with Bar Handle and Regulating Stem

- Material: 316 Stainless Steel (corrosion-resistant alloy)

- Pressure Rating: 5000 psi working pressure (hydro-tested)

- Stem Type: Regulating stem with non-rotating tip

- Cv Coefficient: 0.75

- Finish: Precision-machined body, passivated for hygienic service

| Cv Coefficient | 0.75 |

|---|---|

| End Size | 44198in |

| End Size 2 | 44198in |

| Inch/Metric | Inch |

| Orifice Diameter | 6.3mm |

| Pressure Rating 316 Stainless Steel at 65 to 100 (-54 to 38 ?C) Temperature | bar, psig |

| Pressure Rating at 100 (38 ?C) Temperature | 345bar, 5000psig |

| Temperature Rating (316 Stainless Steel) | ?C, ?F |

| Temperature Rating with Polyether Ether Ketone (PEEK) Packing | 315?C, 600?F |

| Temperature Rating with Polytetrafluoroethylene (PTFE) Packing | -54 to 232?C, -65 to 450?F |

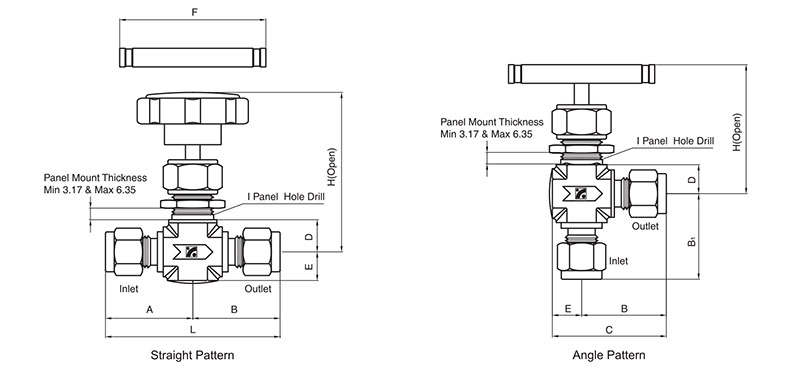

| Dimension A | 35.6mm |

|---|---|

| Dimension B | 35.6mm |

| Dimension B1 | 35.6mm |

| Dimension C | 48.3mm |

| Dimension D | 14.0mm |

| Dimension E | 12.7mm |

| Dimension F | 64.0mm |

| Dimension H | 63.5mm |

| Dimension I | 20.0mm |

| Dimension L | 71.2mm |

Stainless Steel Needle Valve – 1/2" FNPT x FNPT, 5000 psi, Hygienic Regulating Stem (SINV3-S-8-RS)

The SINV3-S-8-RS is a high-performance needle valve constructed from solid 316 stainless steel for hygienic fluid processors and pressure systems demanding fine-tuned control and lasting durability. With 1/2" FNPT x FNPT connections, this inline valve is equipped with a non-rotating regulating stem, designed to provide linear flow control without galling or metal shavings—perfect for sensitive instrumentation lines or sanitary process systems.

Rated for 5000 psi, this valve is built to handle demanding system pressures in compressed gas, chemical transfer, or steam applications. The low Cv coefficient of 0.75 ensures slow, precise modulation for critical dosing, purge, or sampling operations. The bar handle gives the operator tactile control and clear reference points during flow adjustment, even when used with gloves in industrial settings.

This model is frequently deployed in Clean-in-Place (CIP) instrumentation, OEM process panels, sanitary stainless steel fittings layouts, and pressure-sensitive test environments where precise fluid control is critical.

Key Benefits

- 316 stainless steel construction for superior resistance to corrosion, temperature, and process media

- Regulating stem design protects sealing surfaces and minimizes stem wear over repeated cycles

- FNPT x FNPT format integrates directly into sanitary or high-pressure process systems

- Supports hygienic valve installations and CIP instrumentation compliance

- Bar handle allows precision flow modulation in real-time field conditions

- Excellent control in hygienic fluid processing and industrial gas environments

Typical Applications

- Lab gas and chemical control loops

- Skid-mounted Clean-in-Place (CIP) instrumentation systems

- Biotech sampling stations and analytical metering

- OEM valve banks requiring precise fluid control

- Food-grade and pharmaceutical hygienic valve assemblies

- Medium- and high-pressure corrosion-resistant alloy tubing systems

Looking for a needle valve that delivers true control, reliability, and sanitary-grade durability? The SINV3-S-8-RS balances responsive flow regulation with uncompromising construction—making it an ideal choice for precision OEM builds and high-integrity processing environments.

| Swagelok® | SS-1RS8 |

|---|