SINV3-S-8-RS-KH-PE

Stainless Steel Needle Valve – 1/2" OD | PEEK Seats | Phenolic Handle | 5000 PSI

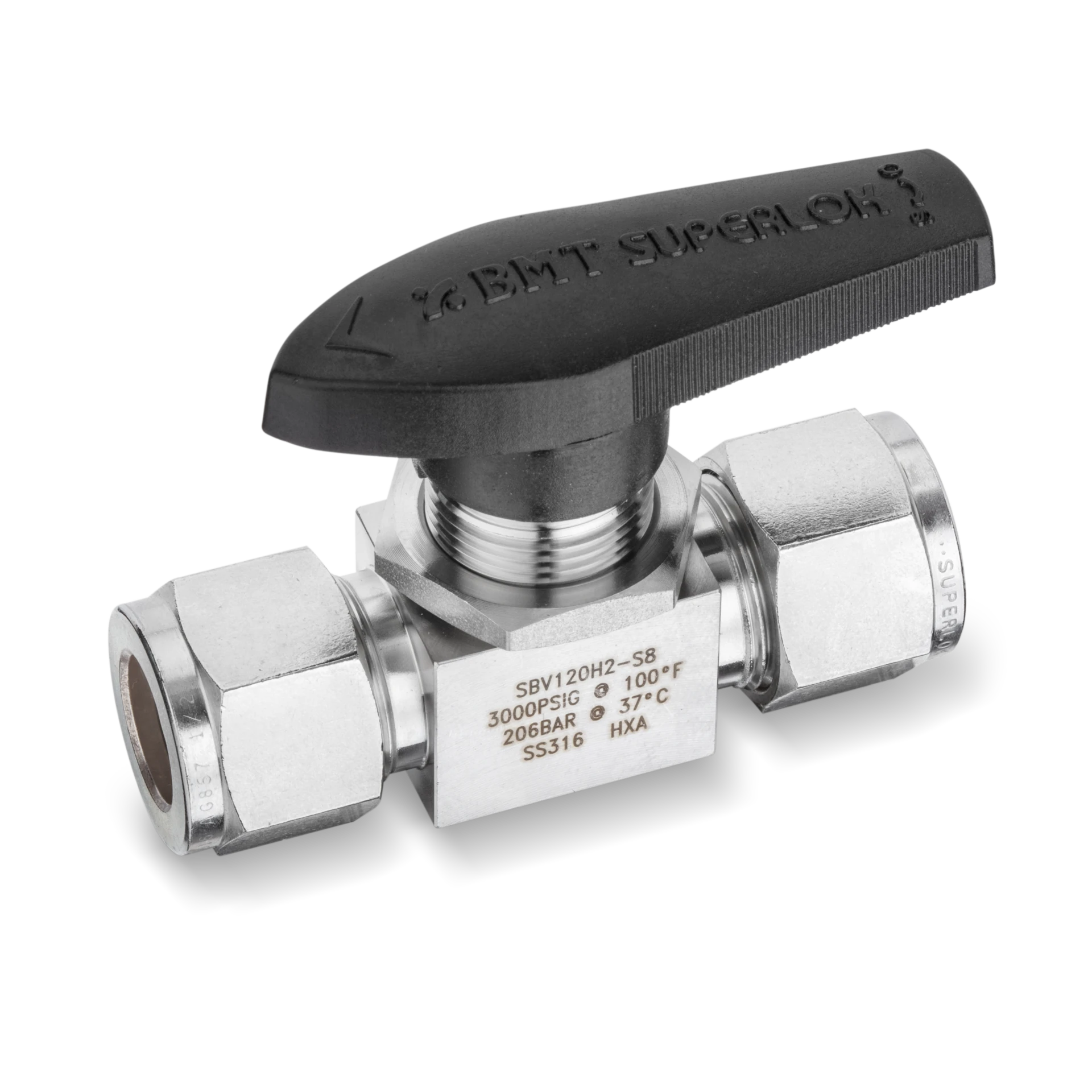

- Model: SINV3-S-8-RS-KH-PE (1/2″ tube OD, PEEK seat, phenolic handle)

- Type: Needle Valve (precision throttling and shutoff valve)

- Body Material: 316 Stainless Steel, Alloy 400, Brass

- Connection Type: 1/2″ Tube OD

- Cv Coefficient: 0.75

- Pressure Rating: 5000 PSIG

| Cv Coefficient | 0.75 |

|---|---|

| End Size | 44198in |

| End Size 2 | 44198in |

| Inch/Metric | Inch |

| Orifice Diameter | 6.3mm |

| Pressure Rating 316 Stainless Steel at 65 to 100 (-54 to 38 ?C) Temperature | bar, psig |

| Pressure Rating at 100 (38 ?C) Temperature | 345bar, 5000psig |

| Temperature Rating (316 Stainless Steel) | ?C, ?F |

| Temperature Rating with Polyether Ether Ketone (PEEK) Packing | 315?C, 600?F |

| Temperature Rating with Polytetrafluoroethylene (PTFE) Packing | -54 to 232?C, -65 to 450?F |

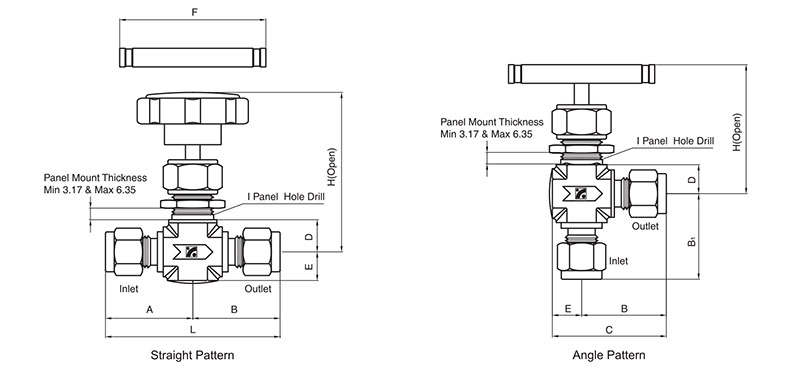

| Dimension A | 35.6mm |

|---|---|

| Dimension B | 35.6mm |

| Dimension B1 | 35.6mm |

| Dimension C | 48.3mm |

| Dimension D | 14.0mm |

| Dimension E | 12.7mm |

| Dimension F | 64.0mm |

| Dimension H | 63.5mm |

| Dimension I | 20.0mm |

| Dimension L | 71.2mm |

Stainless Steel Needle Valve – 1/2" OD | PEEK Seats | Phenolic Handle | 5000 PSI (SINV3-S-8-RS-KH-PE)

Designed for high-purity and high-pressure service, this valve is frequently used in Clean-in-Place (CIP) systems, OEM skids, sanitary process loops, and laboratory instrumentation panels. The panel-mountable body helps simplify system layouts while maintaining accessibility for operators. Its blowout-proof stem adds an essential safety layer, protecting against unexpected disassembly during pressure cycling.

Engineers rely on this valve when precise throttling is required in clean gas delivery, chemical dosing, or industrial control setups. With a Cv rating of 0.75, it balances flow capacity with fine adjustment, making it ideal for both small-scale test environments and large-scale production systems. Designed for longevity, the valve maintains reliable sealing and smooth operation over repeated cycles, even when exposed to aggressive fluids or temperature variations.

The SINV series offers flexibility with both straight and angle body designs, as well as multiple stem tip options to match specific system needs. This adaptability allows the valve to be integrated across diverse process applications without sacrificing performance or safety. From hygienic operations to rugged industrial duty, it provides engineers with confidence in both precision and durability.

Key Benefits

Control: Precise throttling with 0.75 Cv flow and low-torque phenolic handle

Durability: PEEK seat and corrosion-resistant body extend service life

Safety: Blowout-proof stem for high-pressure system protection

Compatibility: Integrates with 1/2″ tube systems and Swagelok® style instrumentation layouts

Material: Mixed metal body for broad chemical resistance and hygienic performance

Typical Applications

- Clean-in-Place (CIP) instrumentation

- Gas analyzers and metering systems

- Original Equipment Manufacturer (OEM) process skids

- Lab flow and chemical feed control setups

- Hygienic valves and sanitary process assemblies

Looking for a Swagelok® alternative needle valve with cleanroom compatibility and rugged control? The SINV3-S-8-RS-KH-PE delivers precision, chemical resistance, and dependable operation for critical applications.

| Swagelok® | SS-1RS8-PK |

|---|