Menu

Close

- Home

- Catalog

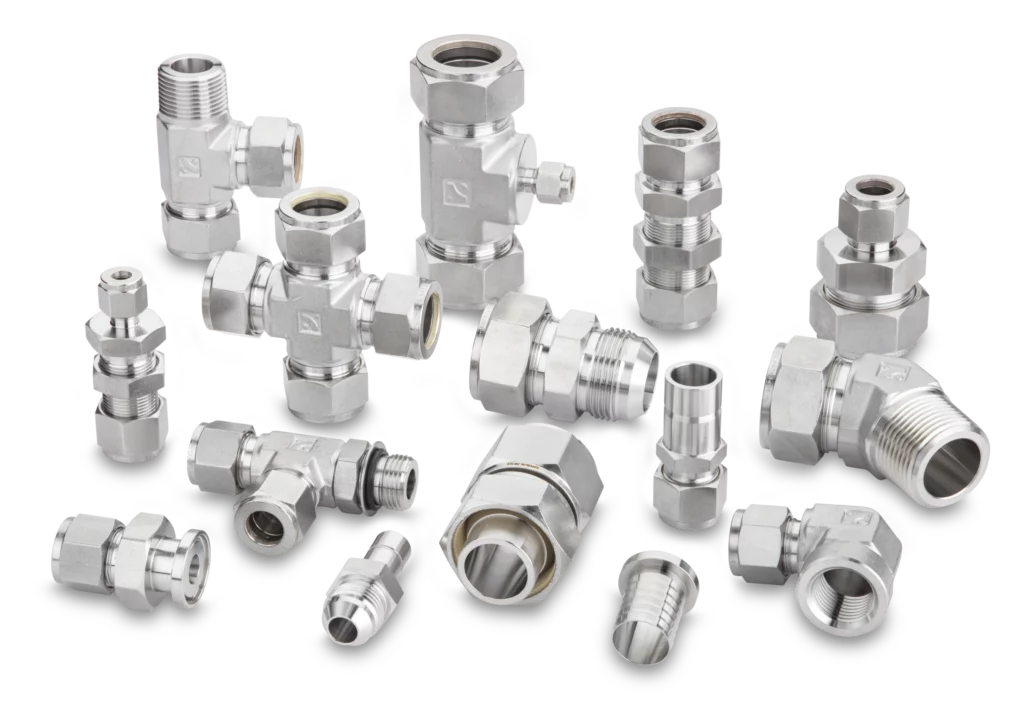

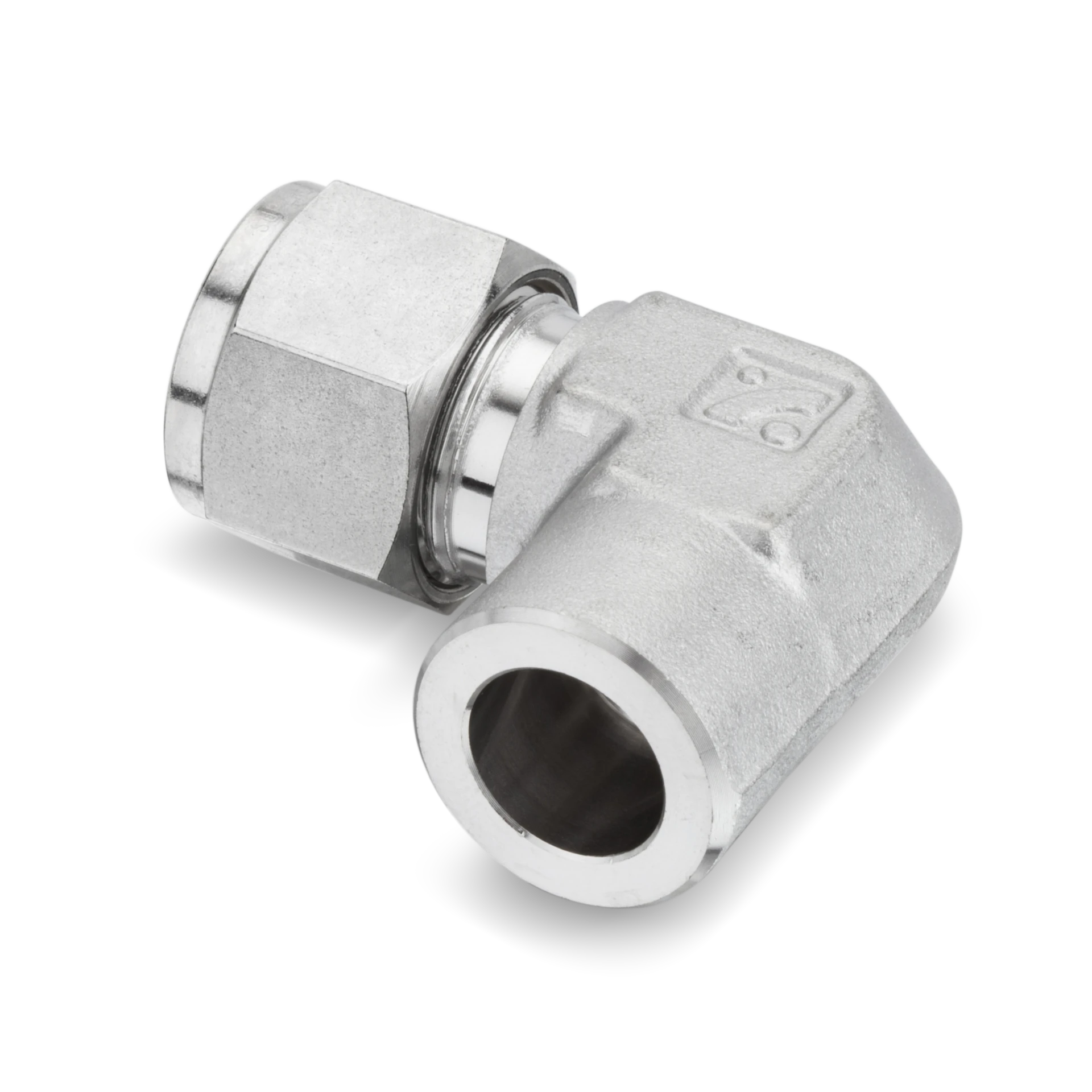

- Tube Fittings

- Pipe Fittings

- Valves

- Quick Connects

- Flare, Society of Automotive Engineers (SAE), and Face Seal Fittings

- Fittings

- Valves

- Check Valve

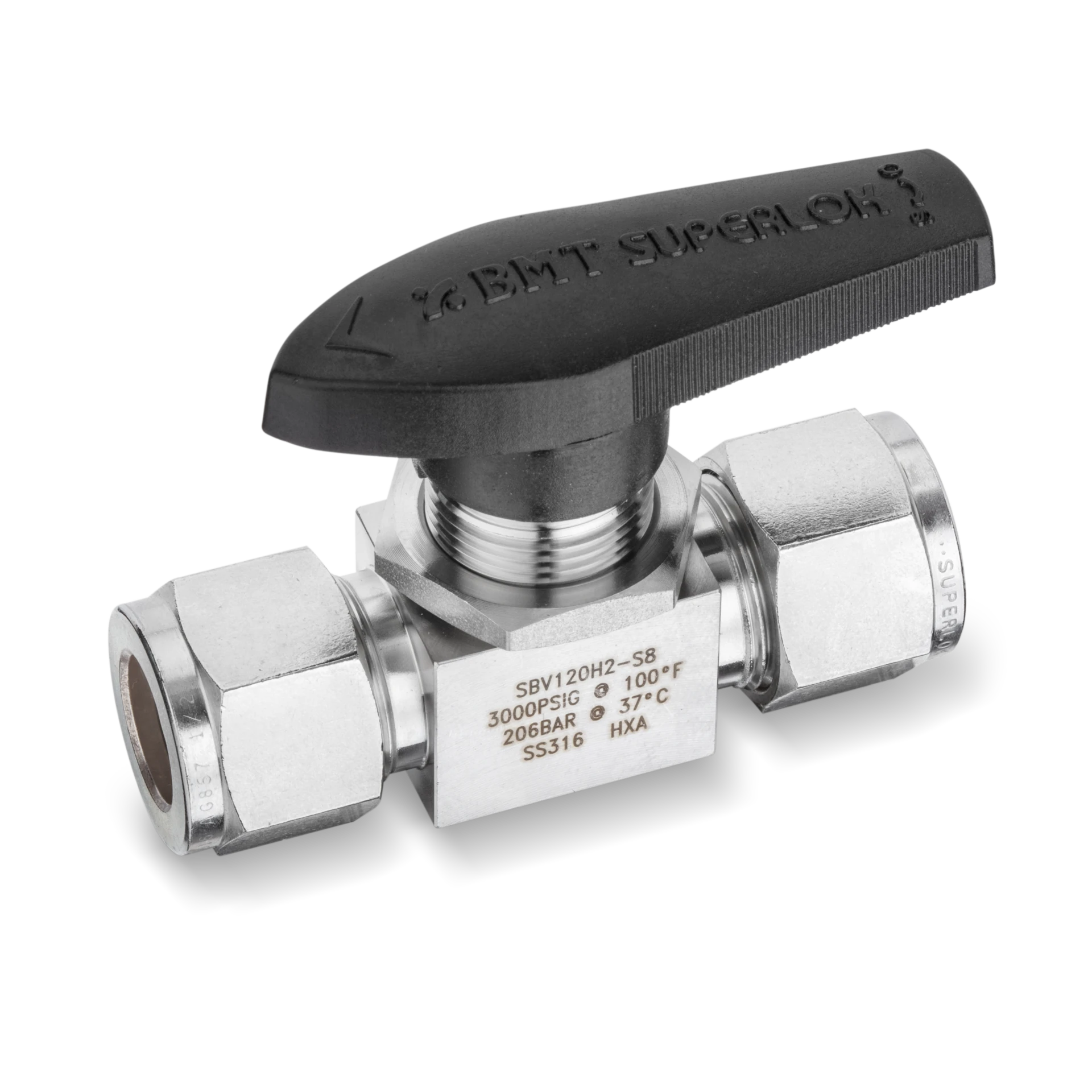

- Stainless Steel Ball Valves

- Stainless Steel Pressure Relief Valves

- Stainless Steel Needle Valve

- Gauge Valves

- Stainless Steel Manifold Valves

- Inline Filter

- Plug Valves

- Purge Valves

- Stainless Steel Bleed Valves

- Toggle Valves

- Block and Bleed Valves

- Stainless Steel UHP Diaphragm Valves

- UHP Check Valves

- Products

- Distributors

- Industries

- More

Close

- Home

- Catalog

- Tube Fittings

- Pipe Fittings

- Valves

- Quick Connects

- Flare, Society of Automotive Engineers (SAE), and Face Seal Fittings

- Fittings

- Valves

- Check Valve

- Stainless Steel Ball Valves

- Stainless Steel Pressure Relief Valves

- Stainless Steel Needle Valve

- Gauge Valves

- Stainless Steel Manifold Valves

- Inline Filter

- Plug Valves

- Purge Valves

- Stainless Steel Bleed Valves

- Toggle Valves

- Block and Bleed Valves

- Stainless Steel UHP Diaphragm Valves

- UHP Check Valves

- Products

- Distributors

- Industries

- More

X

- No products in the list