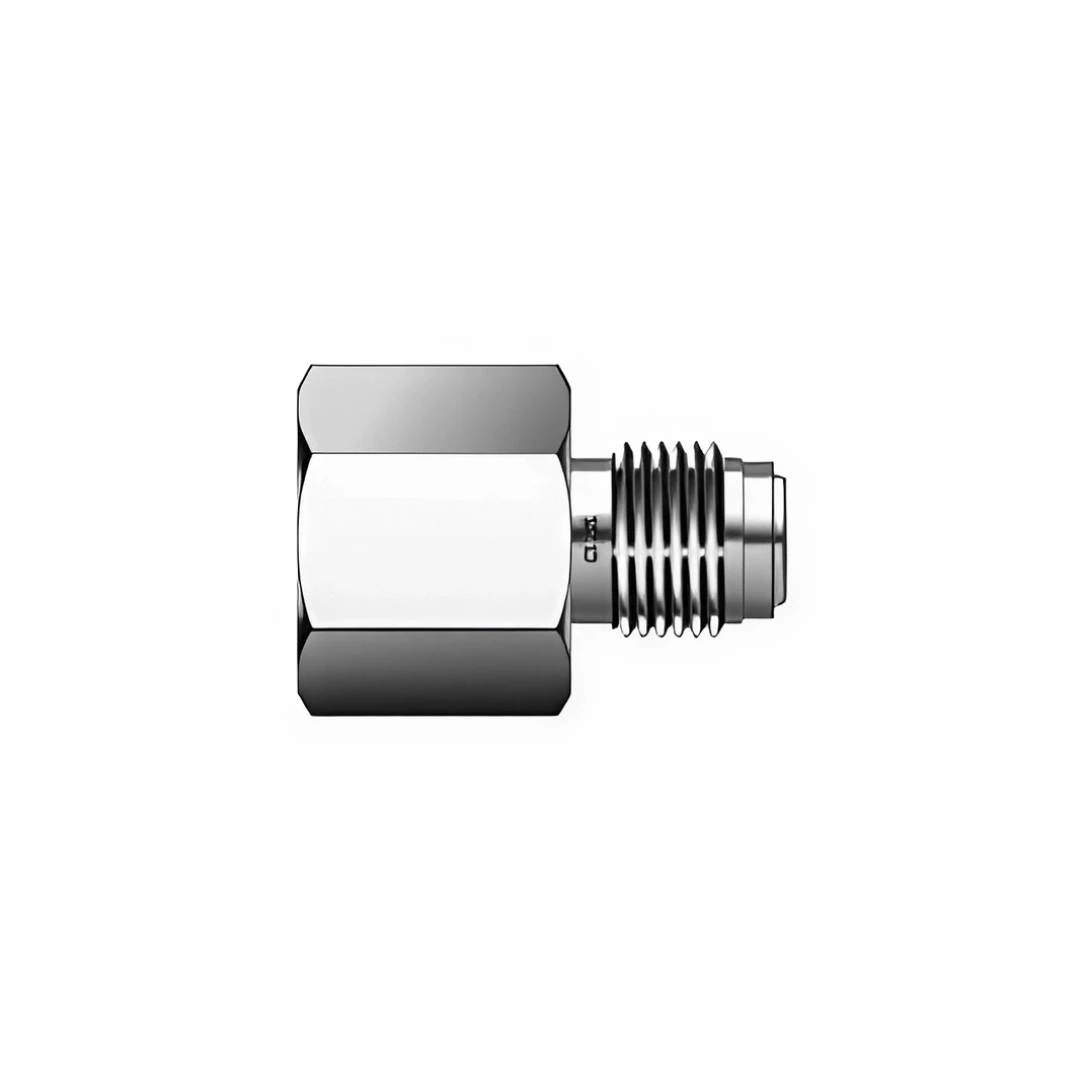

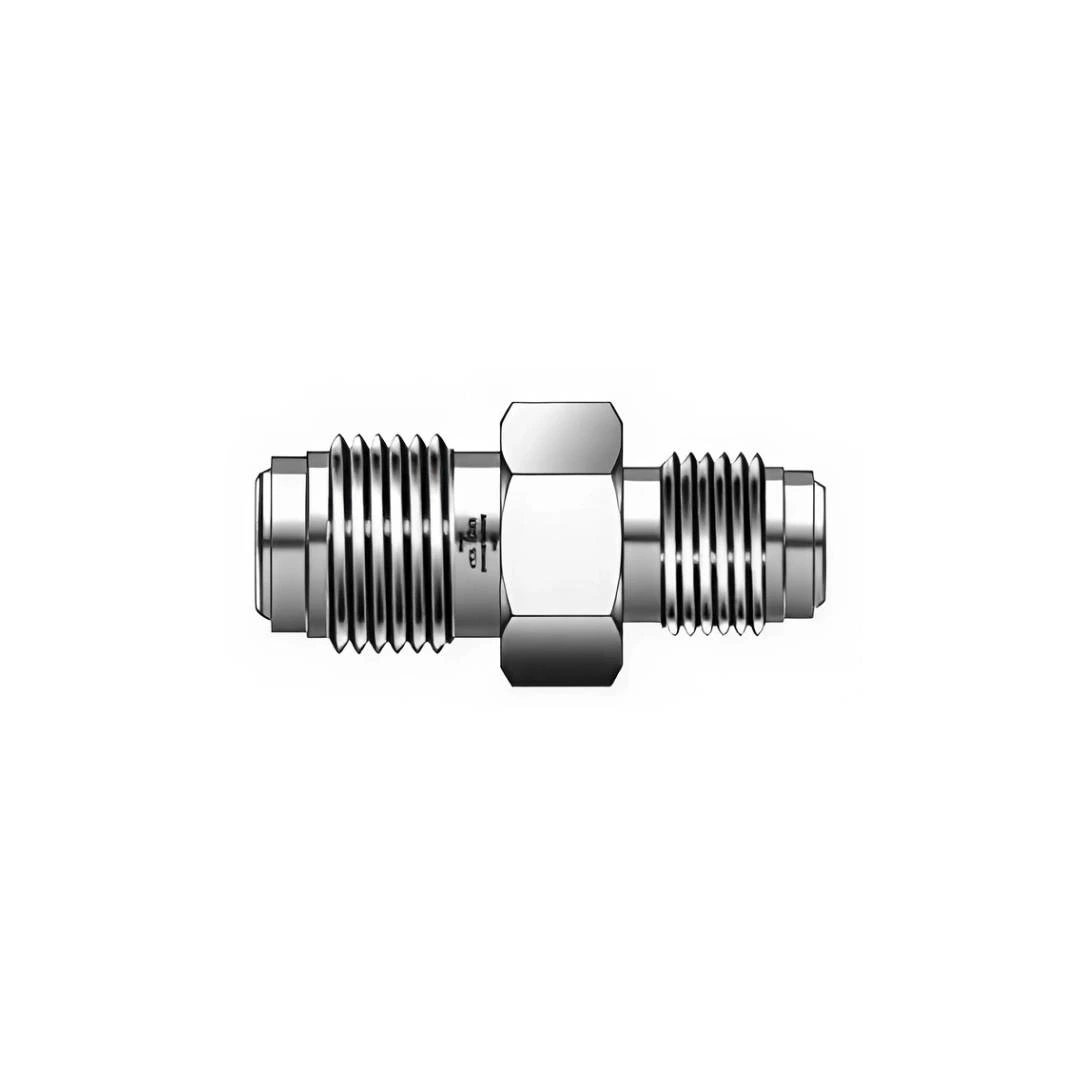

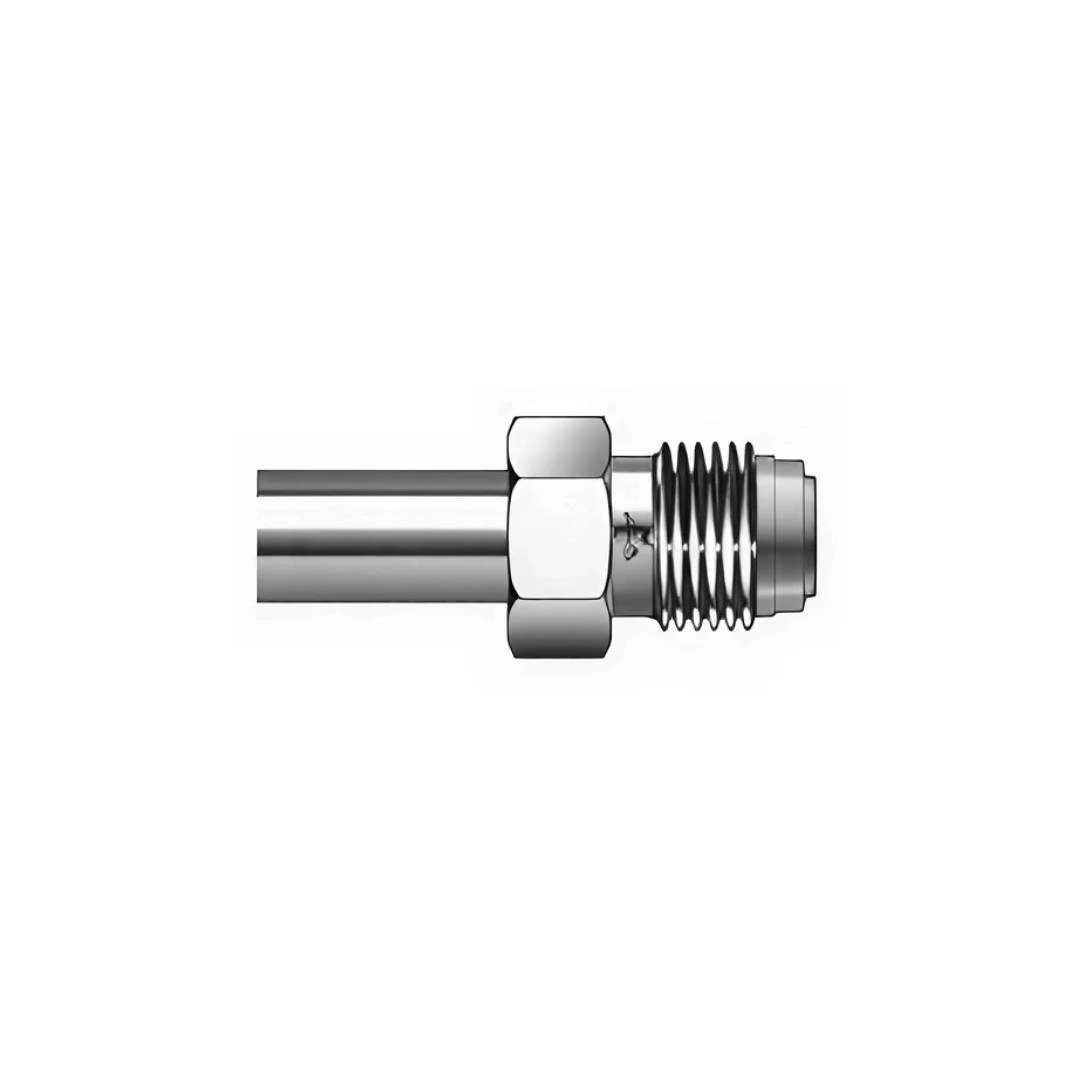

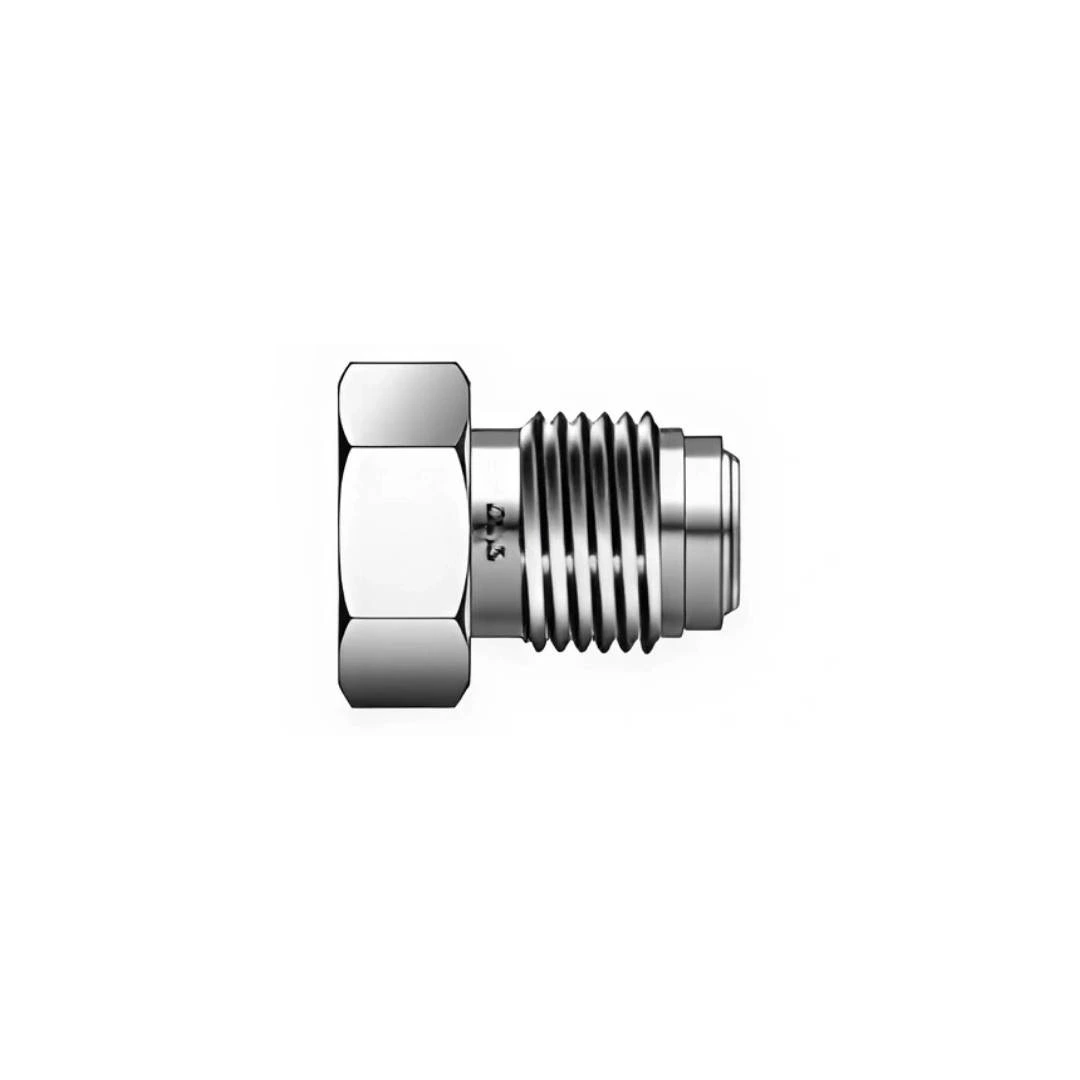

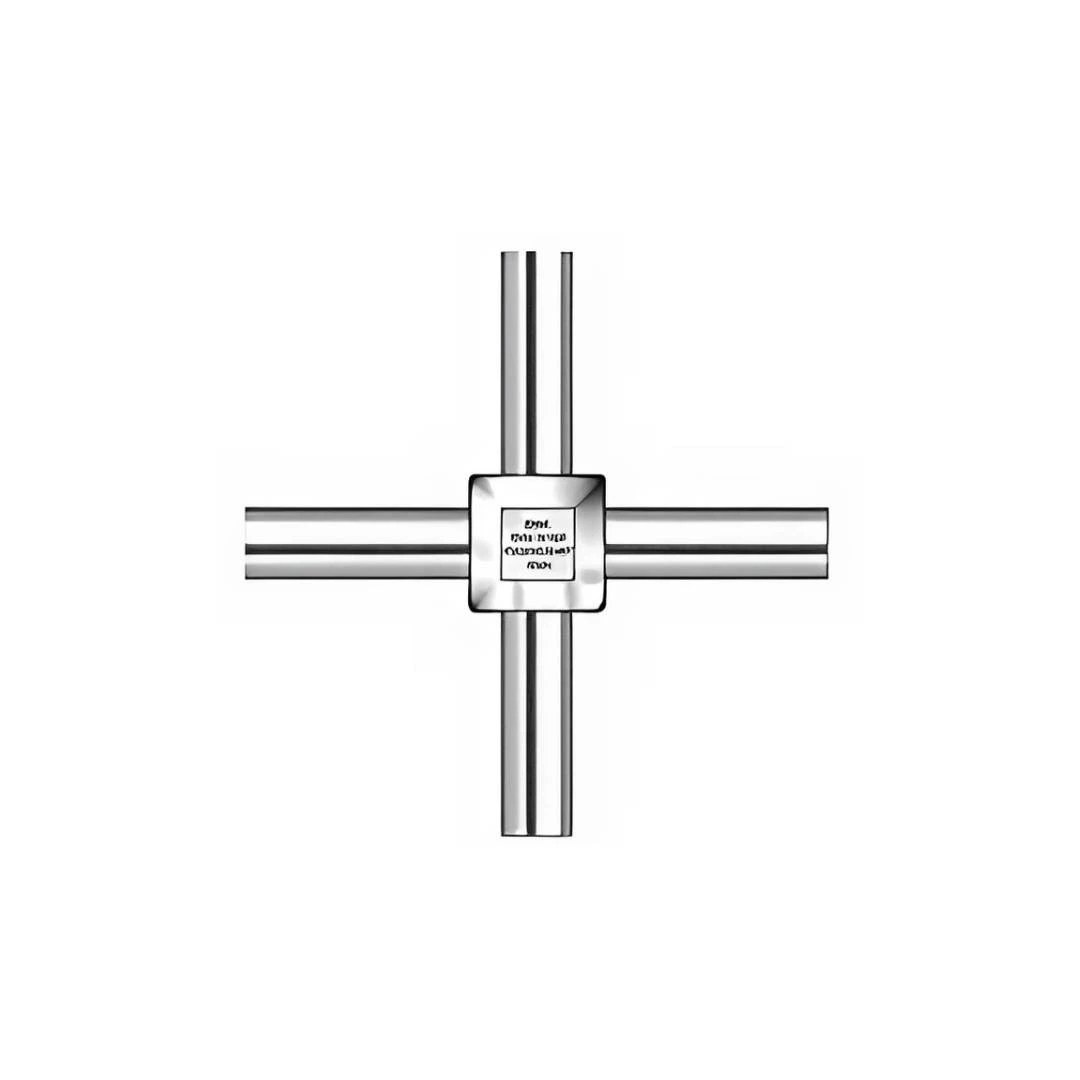

Ultra High Purity Fittings

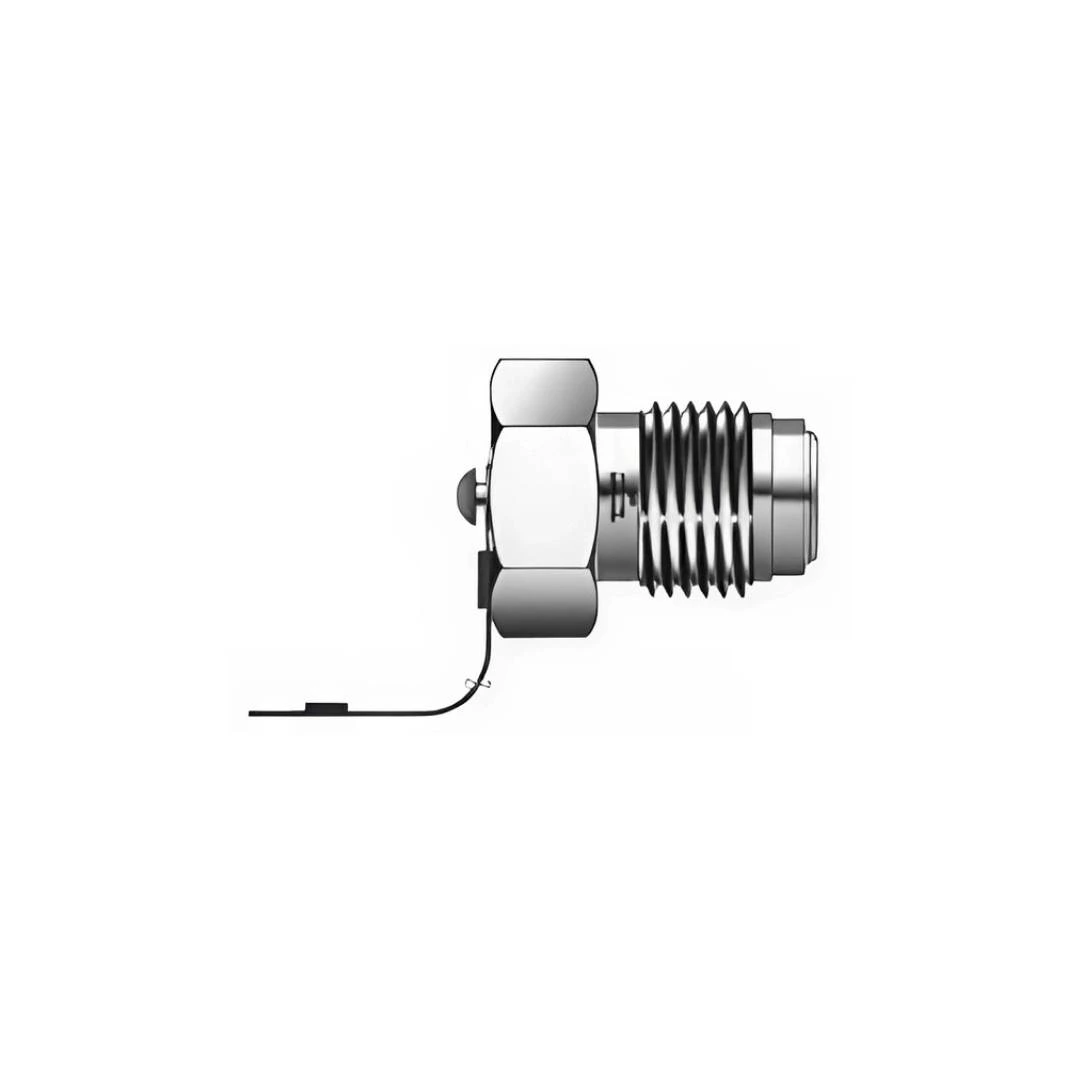

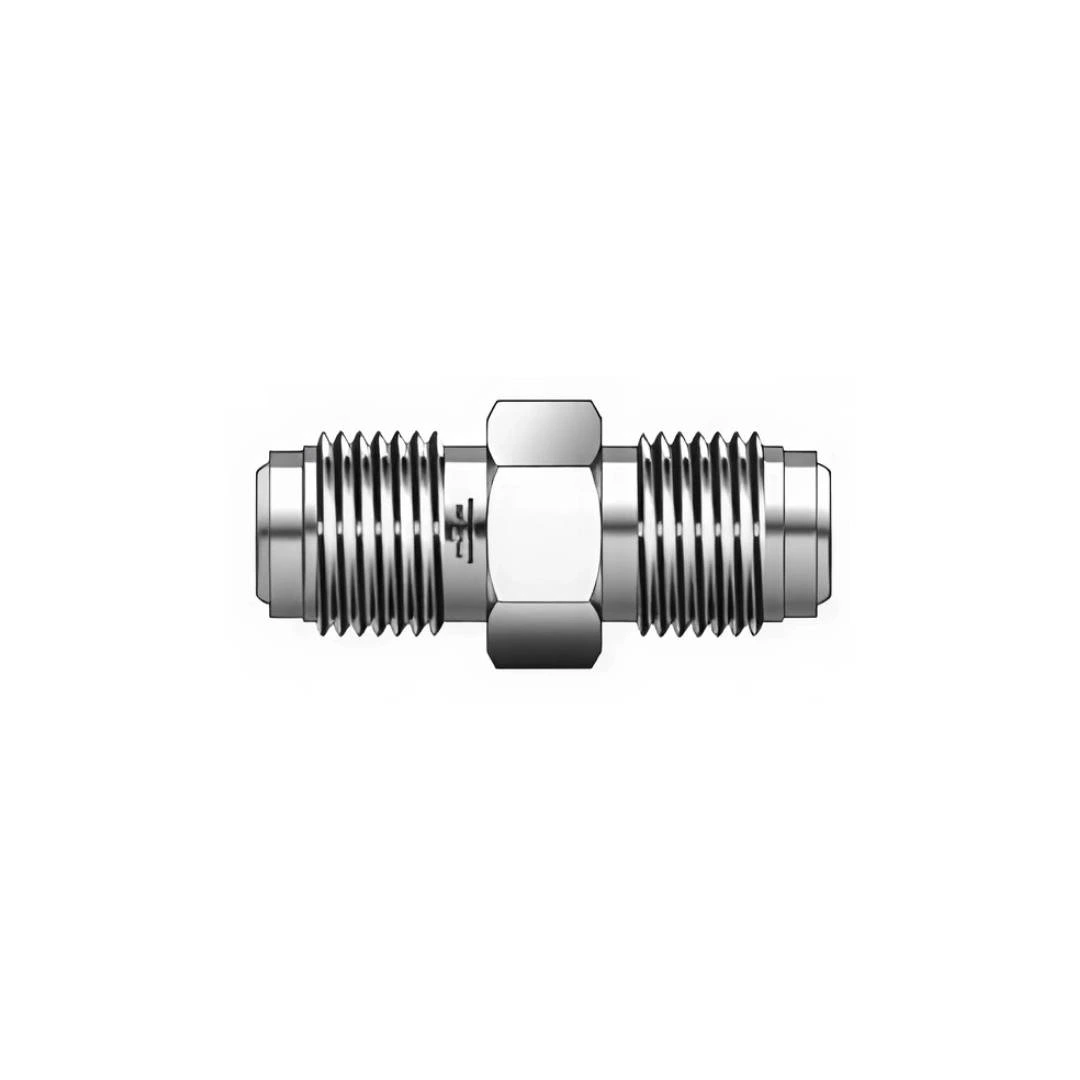

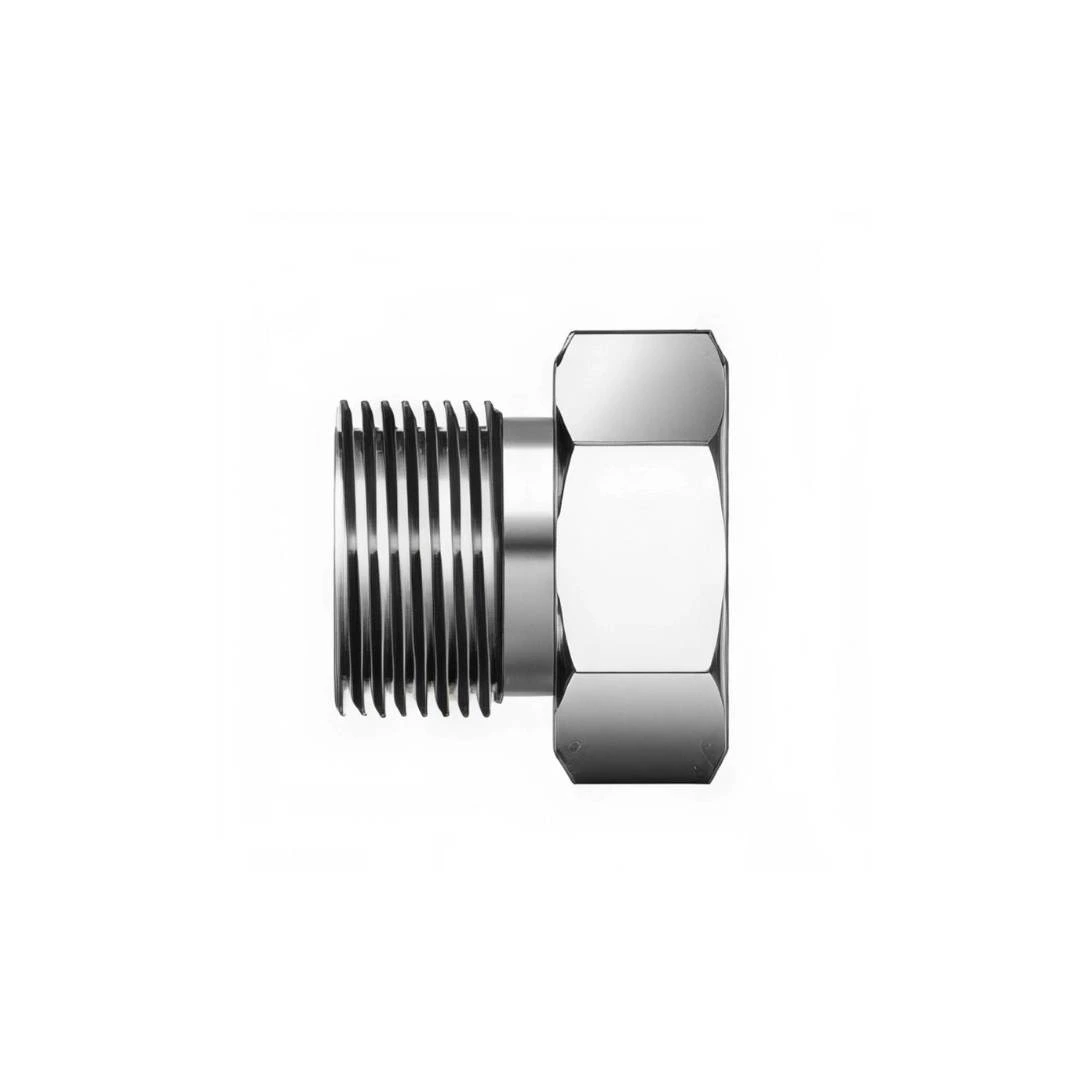

Weld Fitting Ultra High Purity by SuperlokUSA®

More Info

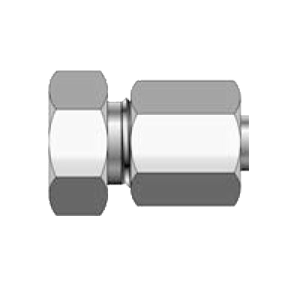

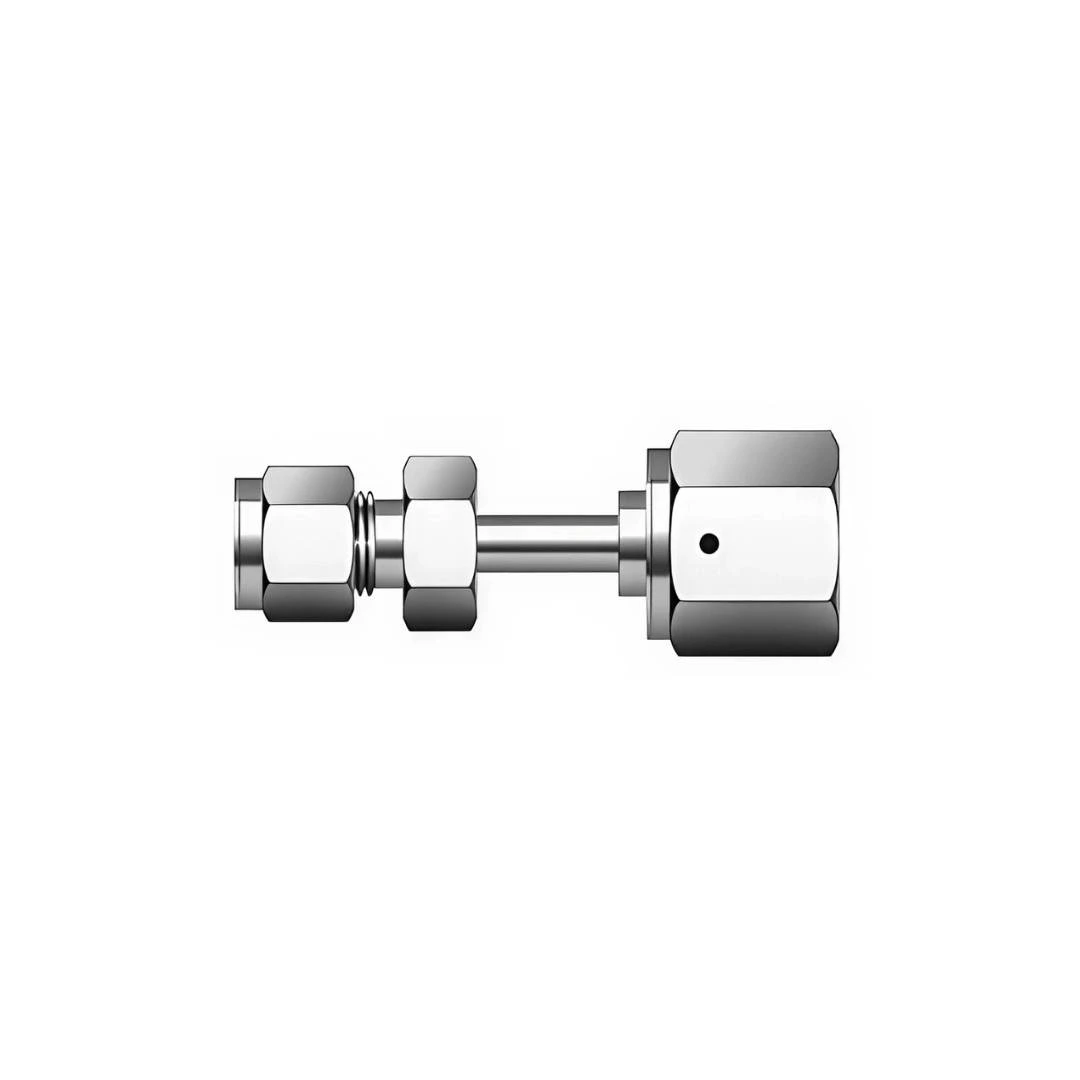

Technicians can assemble, take apart, and reinstall our ultra high purity fittings without fighting the hardware or second-guessing the seal afterward. The components seat cleanly, release cleanly, and come back together with the same predictable feel each time, which matters when you need to maintain a system while keeping downtime low.

The ease of use does not reduce performance. Each one is machined with consistent tolerances so the ferrules grip the tubing the way they are meant to. The compression load stays uniform every time they are tightened. A reused fitting still behaves like a new one, which gives teams the freedom to:

- modify layouts

- add new instrumentation

- replace or reroute sections

- complete maintenance without introducing leak points

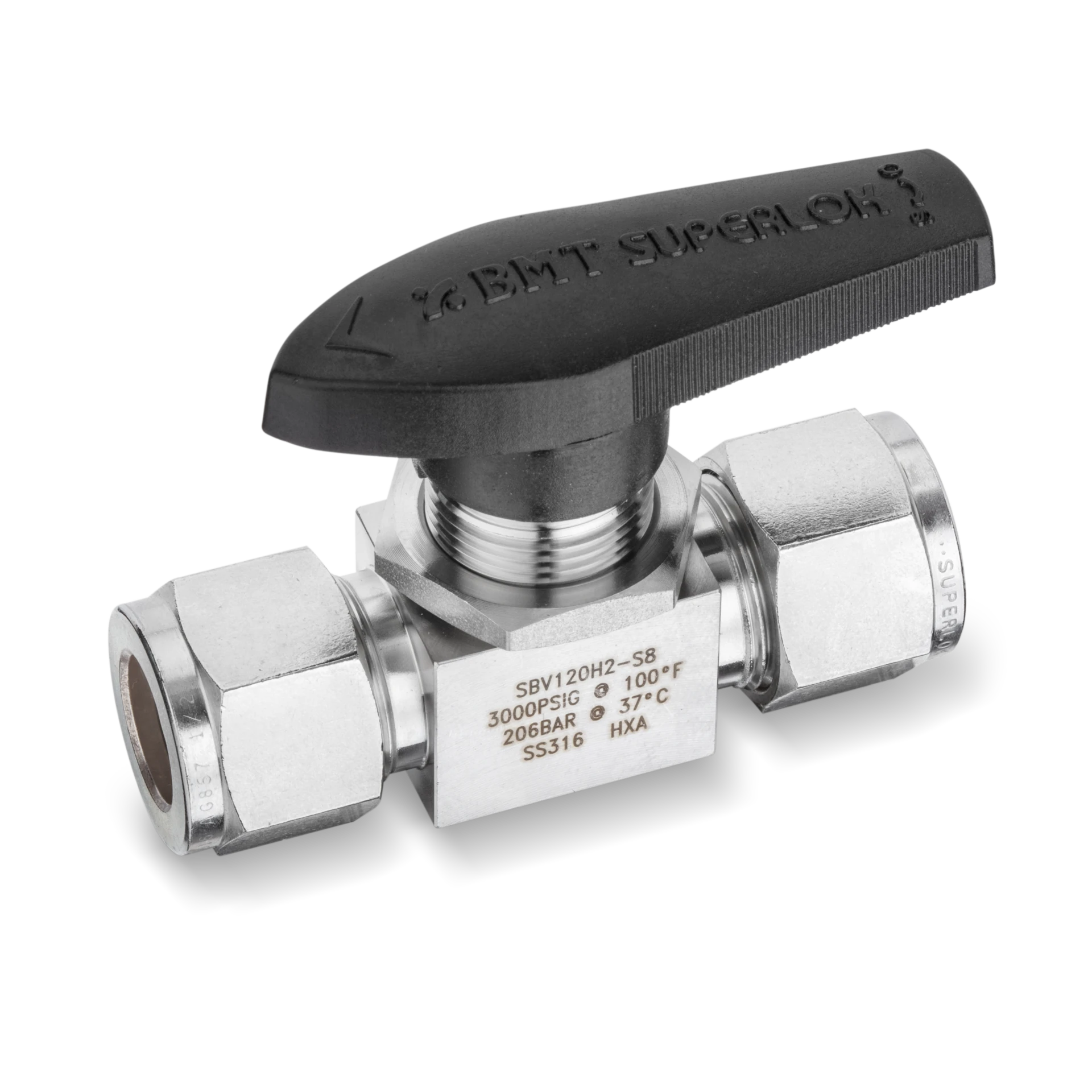

SuperlokUSA’s ultra high purity fittings are also built to take on a wide range of conditions. In sanitary environments, the smooth internal surfaces support cleanliness standards and help maintain uninterrupted purity throughout the system. In industrial settings, the 316 stainless steel and corrosion-resistant alloys perform reliably under vibration, temperature changes, aggressive media, washdowns, and daily operational stress.

You can expect dependable performance in environments such as:

- clean-in-place instrumentation systems

- general industrial pressure systems

- rugged chemical or mechanical settings

Technicians appreciate fittings that do not seize, deform, or force unnecessary part replacements. SuperlokUSA fittings allow systems to stay flexible, maintainable, and stable over time. They are built for teams who want hardware that works cleanly, lasts, and does its job without creating extra complications.

Ultra-High-Purity Swagelok® Alternative Tube Fittings by Superlok

When a system handles gases or fluids that need to stay clean at the molecular level, the fittings have to meet a different standard. Superlok’s ultra-high-purity fittings are built for those environments. They serve applications where particle generation, residue traps, or micro-contamination can derail production. Instead of paying for the Swagelok® name, engineers focus on hardware that consistently delivers purity, stability, and predictable installation.

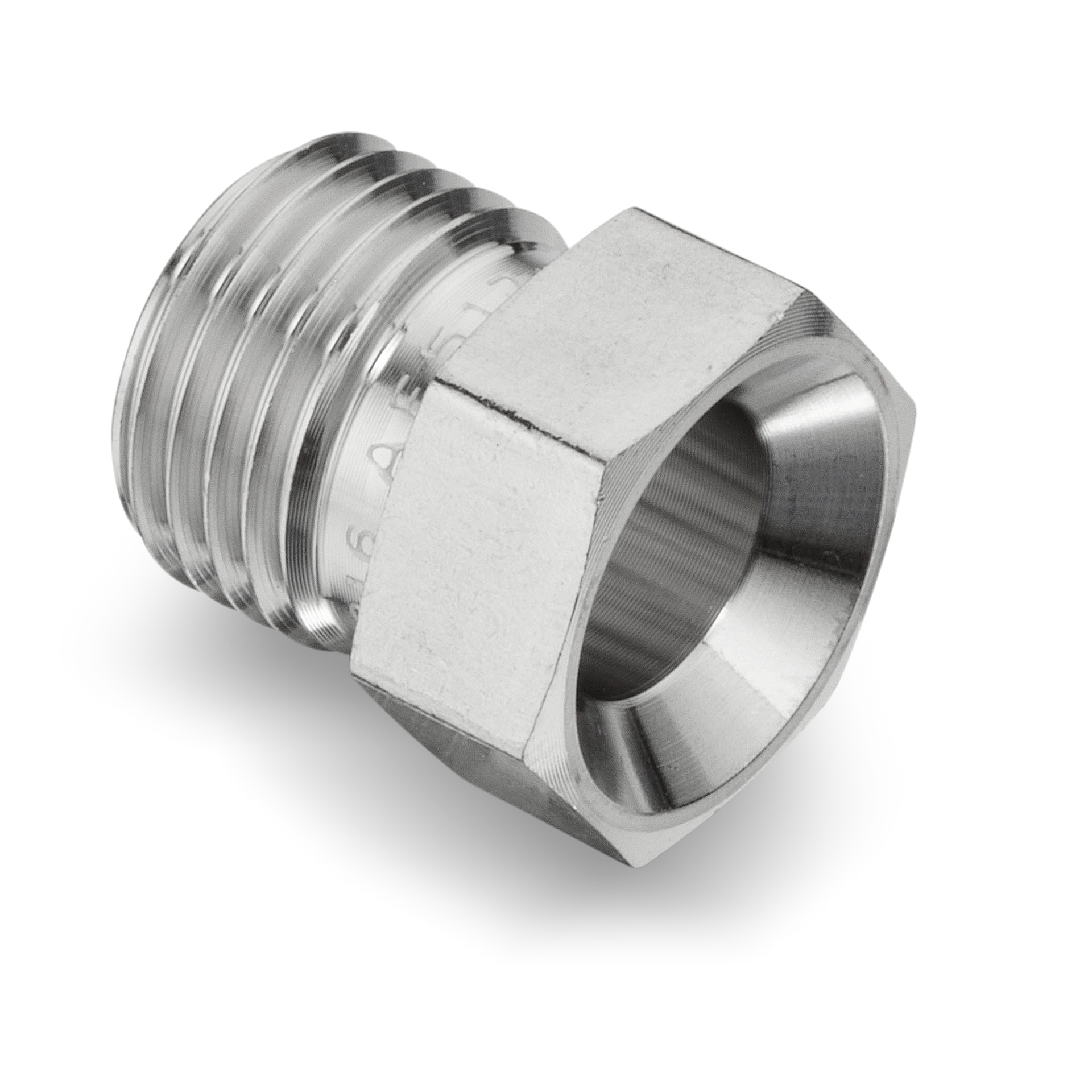

Superlok starts with 316 stainless steel and other corrosion-resistant alloys chosen for chemical integrity and durability. Internal surfaces are finished to keep flow paths clean and uniform, reducing particle shedding and preventing buildup during long production cycles.

The fittings seat with controlled compression and disassemble cleanly. Installers can reposition components without degrading performance or stressing the tubing, which matters in facilities that frequently adjust layouts or upgrade purity protocols. This makes Superlok a practical Swagelok® alternative for teams who want flexibility without sacrificing precision.

Superlok ultra-high-purity fittings also maintain consistent sealing behavior during vibration, thermal changes, and repeated system cycling. The ferrules engage evenly, hold their grip, and support long-term reliability without extra maintenance work. Technicians get hardware that installs cleanly, responds predictably, and stays stable through real-world operating conditions.

For operations that need high purity, dependable uptime, and room to scale, Superlok delivers a clear advantage. You get cleanliness, consistency, and performance that matches the strict expectations of UHP environments, without the inflated price tag or procurement friction.

A Legacy Manufacturer Alternative Parts Finder Near

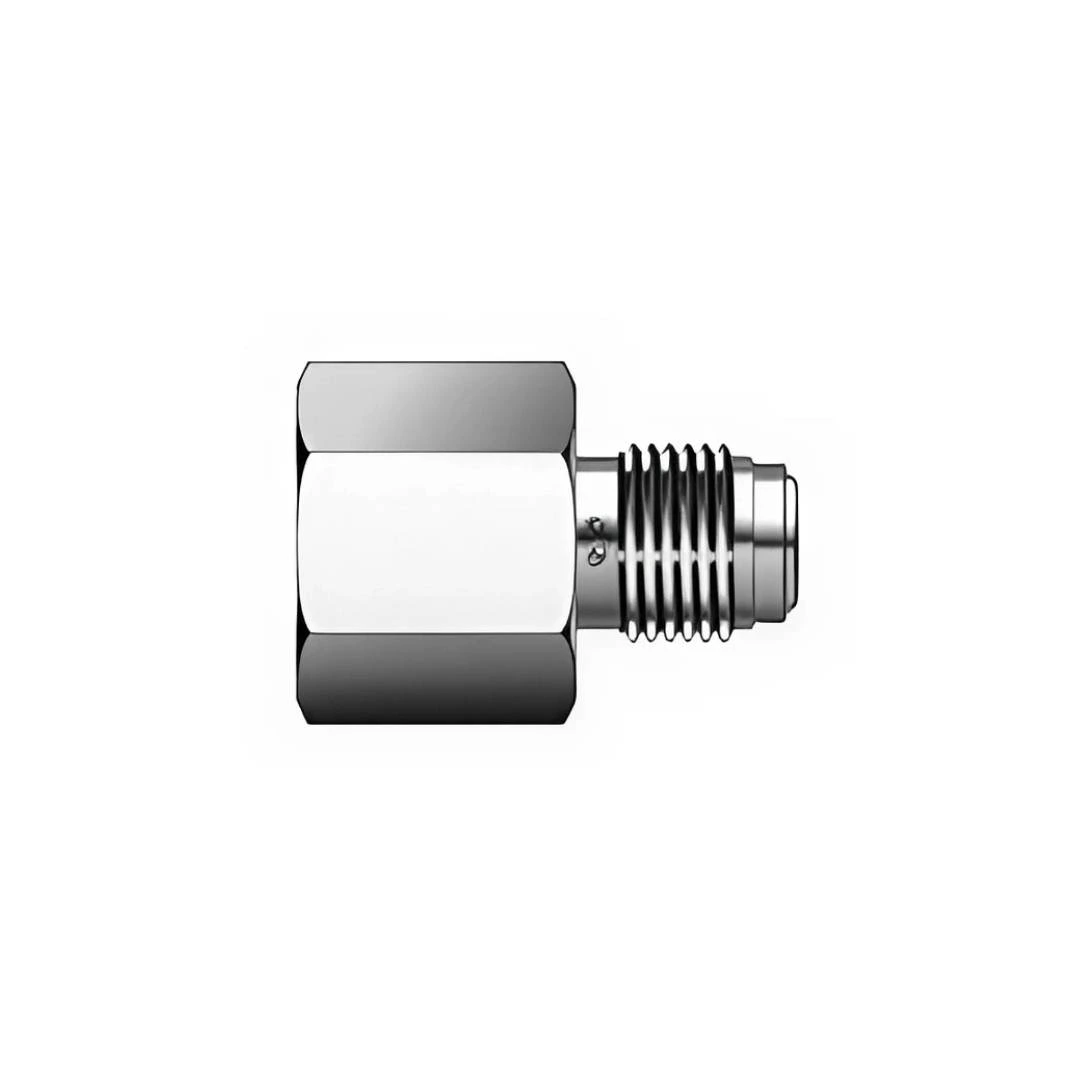

Superlok’s ultra-high-purity tube fittings follow the same critical dimensions, thread profiles, and sealing geometry used by Swagelok®, Hy-Lok®, DK-Lok®, Ham-Let®, and Parker® instrumentation fittings. The match is precise, which means technicians can drop them into existing UHP gas or fluid systems without redesigning lines or changing tube runs.

All nuts, bodies, and threads are manufactured from 316 stainless steel with tolerances held to ASME B1.1 specifications. This level of consistency supports clean, repeatable sealing in environments where purity, vibration control, and leak-tight performance matter.

SuperlokUSA backs its compatibility with certified third-party testing that verifies proper cross-brand fit and high-pressure integrity. For teams sourcing Swagelok® alternatives in UHP applications near Selden, Superlok provides a reliable, cost-controlled option that meets strict cleanliness and performance requirements.

Installation & Maintenance Best Practices

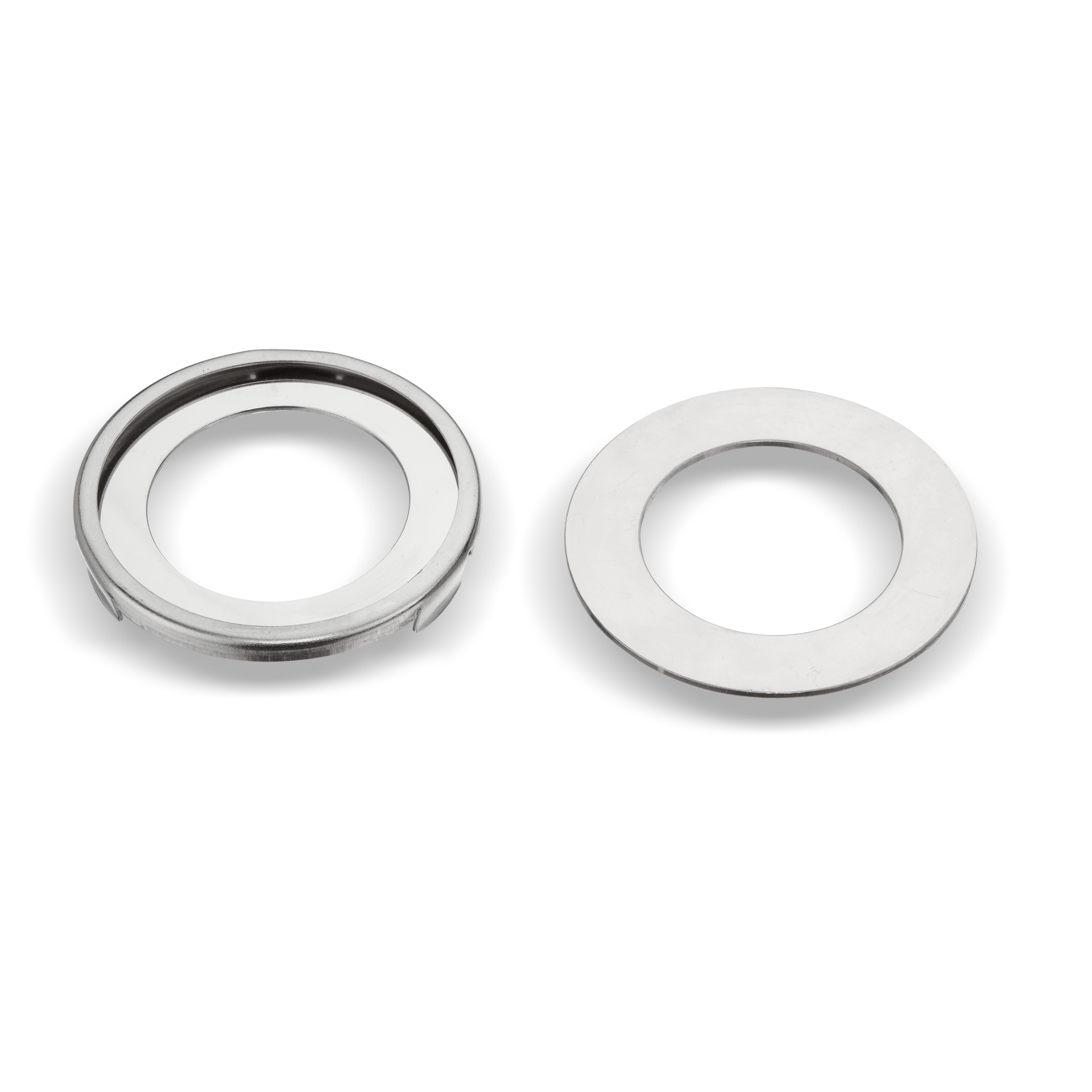

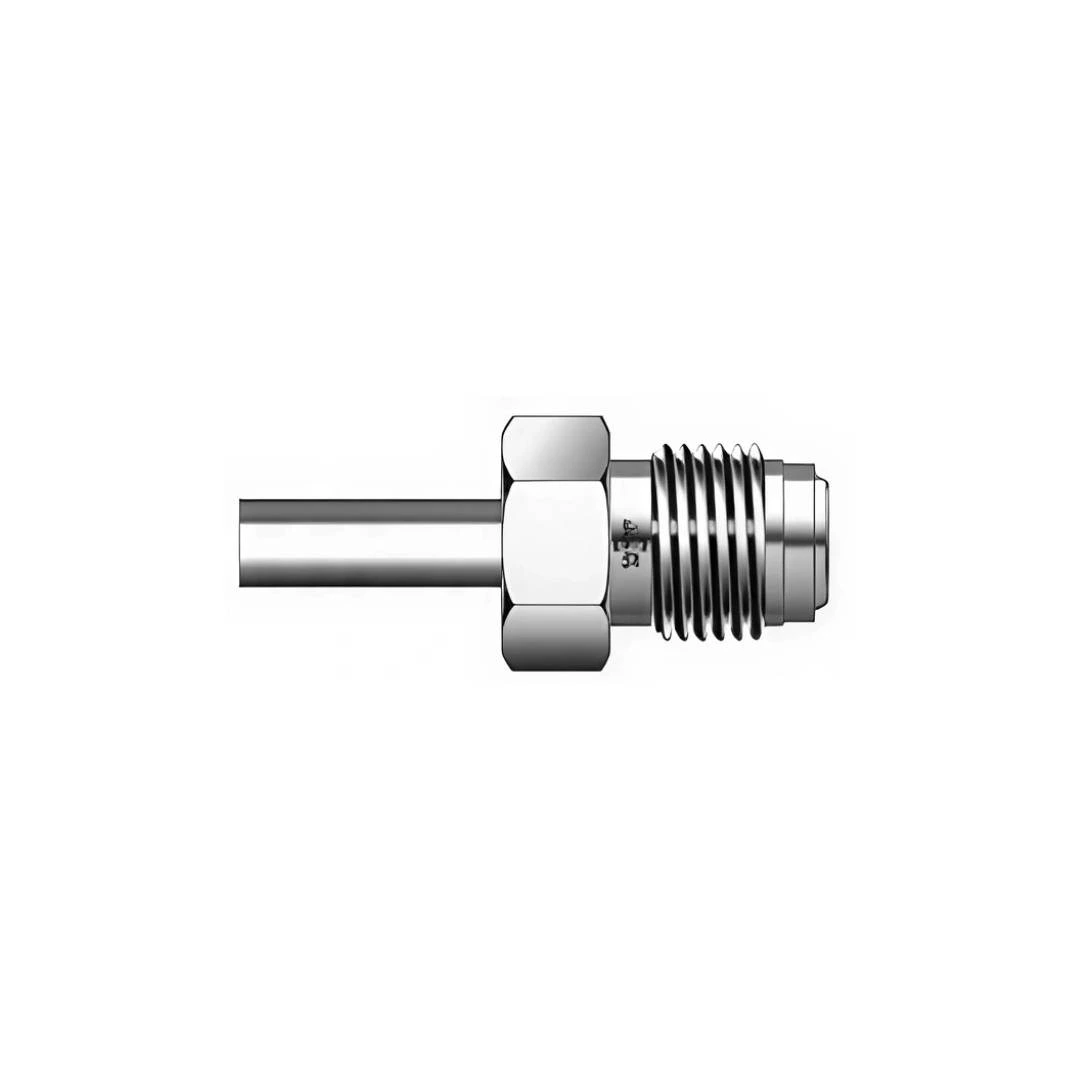

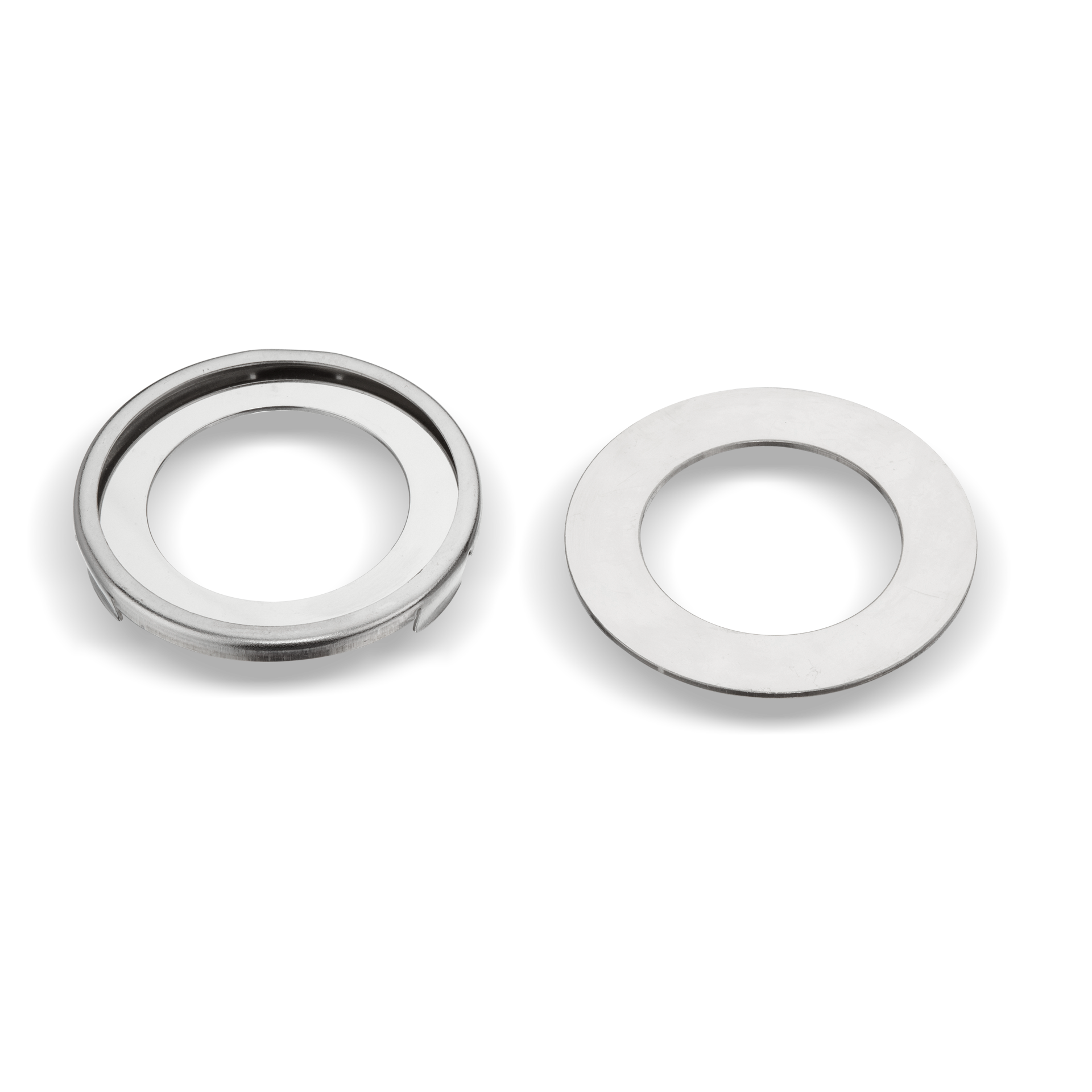

Superlok’s ultra high purity fittings are installed with careful attention to how the tube faces meet and how each weld is positioned, ensuring the joint stays clean and free from anything that could compromise purity in semiconductor or pharmaceutical lines. Tube ends should be trimmed and finished with a precise 45-degree bevel so the 316 stainless steel surface stays smooth and uniform, reaching a random roughness average under 10 micro-inches to prevent particle release.

- Connect via face seal glands finger-tight then quarter-turn to 25 ft-lbs on 1/4-inch to 100 ft-lbs on 1/2-inch, using gap gauges to confirm gasket compression without tube distortion in high-vacuum lines.

- For high purity fluid processors, install with automatic weld heads and CIP tees for 300°F helium purges that displace oxygen below 0.1 ppm without disassembly.

- Secure the tubing using soft, non-metallic supports spaced about six inches apart so the line can flex naturally as temperatures change without stressing the fittings. After everything is in place, run a helium leak check at one and a half times the maximum allowable working pressure for a full fifteen minutes to confirm the system is completely sealed with no trace leaks forming anywhere in the connection path.

Flush with ultra-pure nitrogen post-install for five volumes, monitoring particulates below 0.01 per cubic foot with laser counters. In sanitary applications, select metal gasket face seal models for SIP compatibility, confirming no residue via TOC analysis under 5 ppb. Quarterly inspections use mass spectrometers for leak rates below 10^-10 scc/sec, checking gaskets for compression set under 0.001 inches.

- Service biannually in Class 100 cleanrooms for gasket inspection and surface wiping with lint-free cloths, followed by ultrasonic rinsing at 100°F and citric passivation to enhance oxide layers against chloride corrosion in corrosion-resistant alloys.

- Re-calibrate weld schedules post-450°F bakeout, logging purge times with flow meters for optimized evacuation.

- Document flush volumes and oxygen traces in logs, linking to system volumes for predictive startup planning in fab protocols.

- For hazardous areas, add purged enclosures, verifying isolation exceeds 10^7 ohms to meet NFPA 496 standards in gas panels.

Quality & Standards Compliance

- Face seal groove tolerances adhere to SEMI F78 of ±0.0004 inches on depth, measured by CMMs for gasket compression within 25-30% to support repeatable sealing.

- Weld prep proofing at 1.5 times rated working pressure (RWP) per API 598 uses helium for integrity below 10^-10 scc/sec, cycling 50,000 connections to simulate repeated make-and-break without gasket fatigue.

- Gland alignment per ISO 5211 ensures coaxiality within 0.002 inches, with FEA modeling velocities at 600 scfm for optimized port geometry.

- Independent SGS testing confirmed full cross-brand compatibility with Swagelok®, Parker®, and Hy-Lok®. Assemblies held 3,000 psig with no leakage, thread damage, or galling.

- Pressure destruction tests documented burst performance at more than four times the rated working pressure. Each unit is serialized, with mill test reports including radiographic inspection to ensure no internal defects greater than 0.0002 inches.

- ASTM E595 outgassing evaluations recorded extremely low emissions, staying below 10⁻¹² torr·L/sec. SEMI E49 thermal-cycle testing showed zero seal movement or performance drift even after 1,500 continuous hours.

- SGS audits also covered seal geometry and helium-based leak inspection, maintaining dimensional consistency tighter than 0.0005 inches. Certificates of compliance (CoCs) are issued under ISO 9001:2015 quality standards.

Frequently Asked Questions

What materials are these parts made from?

What pressure ratings do these support?

Are these compatible with other brands?

How do I select the right size?

What lead times apply?

Can these be used in high-purity applications?

How should unused parts be stored?

What torque specifications guide installation?

Do these support cryogenic service?

Industry Leaders Relying on Superlok

Superlok’s ultra high purity fittings show up in places where equipment is constantly being built, opened, adjusted, and put back into service, and where every connection has to stay clean, tight, and predictable. You’ll find them in semiconductor fabs, biotech cleanrooms, advanced chemical processes, energy plants, and any operation that runs high-purity or high-pressure lines on a daily schedule.

What makes them a fit for these environments is simple. The components are machined from 316 stainless steel and other corrosion-resistant alloys, and the internal surfaces are finished to support clean flow with minimal particle generation. The ferrule system seats evenly and holds steady under vibration, thermal shifts, and system cycling, which keeps operators from chasing leaks or replacing fittings that should have lasted.

Teams also value practicality. Superlok fittings assemble quickly, release cleanly, and can be reinstalled without degrading performance. In industries where uptime is measured in minutes and purity standards leave no room for error, that combination of clean operation and field-friendly installation is a real advantage.

From maintaining stable gas distribution in semiconductor tools to supporting sanitary media transfer in pharma and biotech, Superlok delivers the consistency engineers expect from high-purity hardware. The fittings stay tight, stay clean, and stay reliable, even when systems are demanding and schedules are tight, which is why so many industries keep them in rotation.

The Superlok Advantage

RELIABLE ULTRA HIGH PURITY INVENTORY READY WHEN YOUR SYSTEM NEEDS IT

These operations cannot wait for backorders, extended manufacturing schedules, or unpredictable delivery cycles. Every minute a high purity gas line, chemical feed, or cleanroom process sits idle, production slows and costs rise. SuperlokUSA prevents that problem before it ever starts by maintaining one of the most complete, fully stocked inventories in the country.

Our shelves do not just hold a few popular items. They are stocked with the full range of sizes, configurations, and materials required for semiconductor facilities, biopharmaceutical production, precision laboratories, and any environment where ultra clean operation is mandatory. Every fitting is machined from 316 stainless steel or other corrosion-resistant alloys and finished to maintain immaculate flow paths and consistent sealing performance.

Whether your team is replacing a single component on a gas distribution panel or building an entirely new line from end to end, you have immediate access to the parts you need. There is no scrambling, no piecing together partial shipments across multiple vendors, and no production delay caused by inventory shortages.

With SuperlokUSA, engineers, technicians, and procurement managers can move projects forward with confidence, knowing the hardware is available, consistent, and ready to ship the moment it is required. While other legacy manufacturers often create long lead times, our inventory is built to keep your operations running without interruption.

FAST DELIVERY ANYWHERE IN THE UNITED STATES

When a high purity system is offline, every second counts. Production schedules, research timelines, and critical process controls all depend on stable, uninterrupted flow. SuperlokUSA supports that urgency with a nationwide delivery network designed to move quickly, cleanly, and reliably.

Orders ship from multiple distribution locations across the country to cut down transit times and get hardware to your facility as soon as possible. Packaging is handled with care to protect cleanliness standards. Shipping routes and carrier partnerships are chosen specifically for speed, consistency, and cost control. You do not deal with inflated shipping fees, slow fulfillment cycles, or the long delays that often come with traditional name-brand suppliers.

Whether the order is a single fitting needed to finish a repair or a large build-out for a new cleanroom, your parts arrive on time, handled properly, and ready to install without additional cleaning or preparation. The goal is simple: keep your systems online, keep your team working, and eliminate the frustration of waiting on critical components that should have already been delivered.

Engineers, plant managers, and procurement teams across the country continue choosing SuperlokUSA because we deliver what high purity operations need most: reliable inventory, fast shipping, and fittings that maintain the cleanliness, performance, and stability modern industries expect.