Compressed Natural Gas Product

CNG Fitting by SuperlokUSA®

More Info

Every CNG fitting undergoes factory testing to verify sealing performance under pressure and to ensure leak-free operation across all use cases. These fittings are trusted by system designers and operators working with hygienic fluid processors, clean in place instrumentation, and industrial pressure systems where downtime and fluid loss are unacceptable. Superlok’s precision tolerances and consistent quality make them fully compatible with sanitary stainless steel fittings and other Swagelok®-style components.

In sectors like pharmaceuticals, food and beverage, transportation, and energy, where precise fluid control and contamination prevention are non-negotiable, Superlok CNG fittings give engineers a dependable, high-performance solution that’s easy to spec and ready to install.

Compressed Natural Gas Product Pressure Ratings

| Nominal Spring Size psig(bar) | Cracking Pressure Range psig(bar) | Min. Reseal Pressure psig(bar) | Designator |

|---|---|---|---|

| 1/3 (0.02) | 0~3 (0~0.20) | 6 (0.41) back pressure | 0.3P |

| 1 (0.068) | 0~4 (0~0.27) | 5 (0.34) back pressure | 1P |

| 5 (0.34) | 3~9 (0.20~0.62) | 2 (0.13) back pressure | 5P |

| 10 (0.68) | 7~15 (0.48~1.0) | 3 (0.20) | 10P |

| 25 (1.7) | 20~30 (1.3~2.0) | 17 (1.1) | 25P |

Swagelok® cng Fittings by Superlok

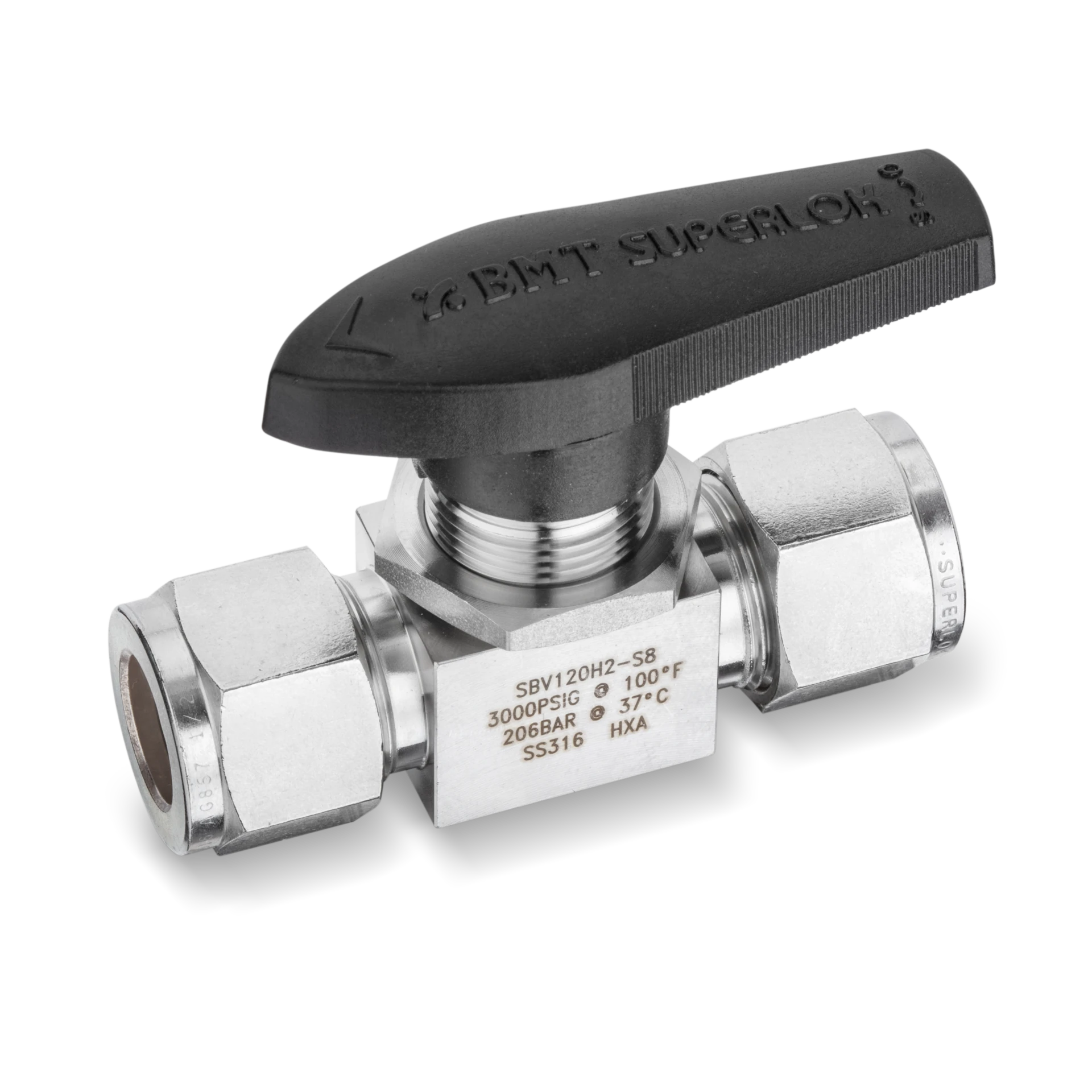

SuperlokUSA®’s compressed natural gas (CNG fittings) are designed to offer seamless interchangeability with Swagelok® and Parker® equivalents. These fittings maintain identical form, fit, and function, with thread tolerances held to ASME B1.1 standards to ensure precise, leak-tight assembly. The result is consistent make-up and full cross-brand compatibility without sacrificing performance or reliability.

Each CNG fitting is manufactured from 316 stainless steel for enhanced resistance to corrosion and long-term exposure to compressed natural gas. Components such as the micro-finished ball, low-torque handle action, and panel-mount-ready designs are engineered to handle demanding environments while maintaining ease of use. From fueling stations to analyzer sampling and industrial gas supply networks, these fittings are tested and certified to meet the rigorous performance demands of high-pressure systems making it a viable Swagelok® alternative.

SuperlokUSA® supplies one of the most complete selections of compressed gas fittings available, with ready-to-ship inventory that minimizes downtime. For operators seeking a direct alternative to legacy brands, Superlok delivers consistent quality, pressure system safety, and precise fluid control without the long lead times or inflated pricing typically associated with premium brands.

Swagelok® Alternate Parts Near

SuperlokUSA® supplies fully interchangeable Swagelok® alternate CNG fittings near you engineered for compressed natural gas systems that require uncompromising safety, sealing performance, and pressure integrity. Designed to have the comparable form, fit, and function of Swagelok® and Parker® CNG components, these fittings allow for seamless integration into both new builds and retrofit applications.

Each fitting is manufactured from 316 stainless steel for maximum corrosion resistance in high-pressure gas environments. Threads are cut to ASME B1.1 standards and held to strict tolerances, ensuring consistent engagement and leak-free sealing across pressure systems. Whether used in mobile fueling equipment, analyzer panels, or pipeline infrastructure, Superlok fittings maintain performance where it matters most.

Certified to meet SGS interchangeability and burst-test standards, these CNG fittings are trusted across hygienic fluid processors, clean in place instrumentation setups, and other precise fluid control applications where reliability is critical.

Installation & Maintenance Best Practices

Superlok CNG fittings require flow direction verification during installation to ensure safe gas delivery in vehicle and dispenser systems. Clean threads with non-abrasive brushes to remove contaminants below 5 microns, ensuring 316 stainless steel fittings achieve random roughness average (Ra) under 32 micro-inches for leak-free engagement without galling. Align connections with system piping using alignment pins for 0.002-inch precision, avoiding misalignment that could cause vibration-induced failures in high-flow refueling setups.

- Torque NPT connections hand-tight then to 18 ft-lbs on 1/4-inch to 110 ft-lbs on 1-inch per ASME B1.20.1, using calibrated torque wrenches to distribute load evenly across the body in pressure systems and minimize distortion under 3,600 psig.

- For high-purity fluid processors, position components downstream of coalescers with isolation valves, integrating clean-in-place (CIP) ports for 250°F nitrogen flushes that clear odorant residues without disassembly.

- Secure with braided hose clamps spaced 8 inches apart to dampen vehicle vibrations, conducting initial proofing at 1.5 times maximum allowable working pressure (MAWP) for 10 minutes with odorized methane to detect seat leaks below 10^-5 scc/sec.

- Re-torque post-thermal exposure to 300°F, logging flow rates with orifice plates to flag fatigue in precise fluid control loops.

- Record pressure drops and cycle counts in maintenance software, benchmarking against Cv ratings to schedule overhauls in refueling stations.

- For vibration service, add dampers upstream, confirming velocity stays under 50 scfm to avert slamming in automated dispensers.

These steps prolong component endurance to 100,000 cycles, curbing backflow incidents in fleet vehicles and CNG stations. Digital tracking optimizes intervals, cutting costs by 30% in continuous operations. Focused alignment and cleaning sustain compliance across diverse automotive and industrial setups with our cng fittings.

Quality & Standards Compliance

Superlok CNG fittings forge from 316 stainless steel per ASTM A182/A479, delivering yield strengths above 80 ksi and hardness 85-95 Rockwell B for fitting resilience under surge flows. Each assembly receives positive material identification (PMI) via optical emission, verifying molybdenum over 2.5% for pitting resistance equivalent numbers (PREN) above 25 in sour natural gas.

- Seat machining holds ANSI NGV 2.0 tolerances of ±0.001 inches on angle, gauged by air plugs and CMMs for uniform contact that ensures zero leakage at 1.5 times rated working pressure (RWP).

- Hydrostatic burst to 4 times design pressure per CSA 12.3 incorporates helium spectrometry for forward flow integrity below 10^-5 scc/sec, simulating 100,000 cycles without poppet flutter.

- Spring load qualification per ASTM F1548 maintains 5-50 psi cracking across sizes, with FEA modeling disc stresses at 3,600 psi to refine geometries for minimal pressure drop.

- Vibration endurance per ASTM D4169 simulates 500 hours trucking, confirming no seat erosion, while chemical immersion per ASTM G31 verifies poppet compatibility.

- Third-party SGS audits furnish metrology data and dye penetrant scans for cracks below 0.001 inches, issuing certificates of compliance (CoCs) under ISO 9001:2015 systems.

- This regimen yields components for 20-year reliability in CNG dispensers and vehicle tanks, outstripping norms for backflow prevention in pressure systems.

Traceability aids DOT PHMSA audits from pipelines to nozzles. Rigorous seat validation guarantees precise unidirectional control with our cng fittings.

Frequently Asked Questions

What materials are Superlok Compressed Natural Gas Products constructed from?

What pressure ratings do these CNG fittings support?

Are these compatible with other manufacturers' products?

How do I choose the right size?

What lead times apply to orders?

Can these be used in high-purity applications?

How should unused CNG fittings be stored?

What torque specifications guide installation?

Do these accommodate cryogenic service?

Industry Leaders Using Superlok

Compressed natural gas systems demand more than just fittings. they require leak-tight performance, long-term reliability, and certified compatibility across every connection point. That’s why Superlok’s 316 stainless steel CNG fittings have become the go-to solution for engineers and operators in pressure systems ranging from fuel dispensers and panel assemblies to vehicle conversion kits and industrial gas distribution skids.

Superlok CNG fittings are trusted across the compressed natural gas sector for their ability to maintain precise fluid control under high pressure, thermal cycling, and vibration. Manufactured to exacting tolerances and verified by third-party testing, these components meet the same performance and sealing integrity you’d expect from Swagelok®. Every fitting is constructed from 316 stainless steel for superior corrosion resistance critical in environments where gas purity, clean in place instrumentation, and hygienic processing are non-negotiable.

Whether you’re outfitting mobile fueling systems, upgrading fueling station manifolds, or maintaining high-purity gas flow in industrial applications, Superlok delivers on what matters most: safety, system integrity, and cost-effective interchangeability. Applications include hygienic fluid processors, pressure systems, corrosion-resistant alloys, sanitary stainless steel fittings, and operations demanding precise fluid control.

Superlok Advantage

NATIONWIDE INVENTORY OF CNG FITTINGS IN STOCK, NO GUESSWORK

SuperlokUSA maintains one of the largest U.S.-based inventories of 316 stainless steel CNG fittings, giving contractors, integrators, and energy developers access to high-quality components without long lead times or backorder nonsense. Whether you're building out fueling infrastructure for compressed natural gas, retrofitting an existing pressure system, or scaling up for fleet deployment, Superlok delivers consistent availability on the fittings you actually use. Every piece is precision-machined to ASME B1.1 tolerances, ensuring a tight seal and cross-brand compatibility with legacy Parker® and Swagelok® systems.

No more juggling multiple vendors or chasing availability we stock the full range of sizes and configurations, all built with corrosion-resistant alloys and engineered for clean gas flow and safety-critical applications.

DEPENDABLE DELIVERY WITHOUT THE GUESSWORK

When you're specifying parts for compressed natural gas systems, availability and fulfillment aren't just nice to have they're critical. SuperlokUSA ships directly from U.S.-based inventory, meaning you’re not gambling on overseas backorders, surprise delays, or broken promises from reps. Orders are fulfilled with care, packed with industry-specific labeling, and shipped with traceable tracking because that’s the standard when your work is being inspected, regulated, and pressurized. We work with established freight partners to keep delivery timelines predictable, and we don’t hide behind hazy lead time disclaimers or inflated rush fees. Whether you're ordering for new installs, system upgrades, or field service kits, we make sure your fittings arrive in good condition, properly spec’d, and ready for install.